Tensile test

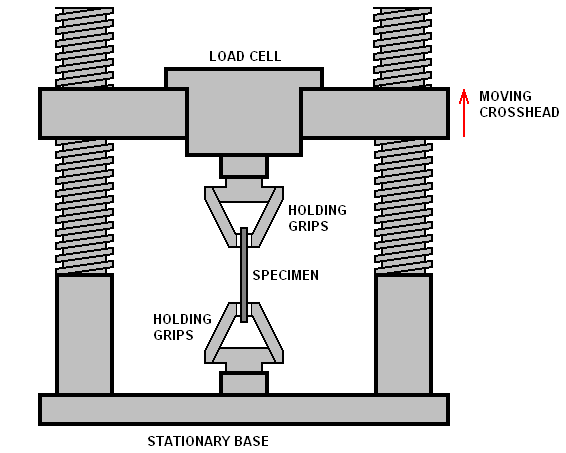

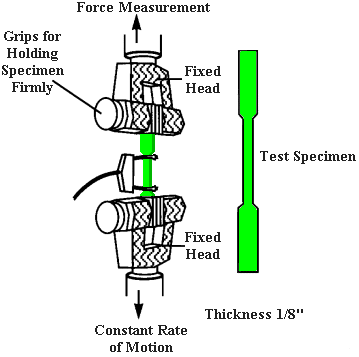

A tensile test is carried out on standard tensile test specimen in universal testing machine. Fig. shows a schematic set up of universal testing machine reflecting the test specimen griped between two cross heads. Fig. shows the stress strain curve for ductile material. Fig. shows the properties of a ductile material. Fig. shows the stress strain curves for wrought iron and steels. Fig. shows the stress strain curve for non ferrous material. Copied from Introduction to Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

Tensile test purpose

The primary use of the testing machine is to create the stress-strain diagram. Tensile test determines the strength of the material subjected to a simple stretching operation. Typically, standard dimension test samples are pulled slowly (static loading) and at uniform rate in a testing machine while the strain ( the elongation of the sample) is defined as: Engineering Strain = E = (change in length)/(original length) = E/Lo and the stress ( the applied force divided by the original cross-sectional area) is defined as: Engineering Stress = E = (applied force)/(original area) =P/Ao The aim of the test is to assess some mechanical characteristics of testing material: its elasticity, ductility, resilience and toughness. There are two kinds of typical diagrams: with distinct yielding limit without distinct yielding limit.

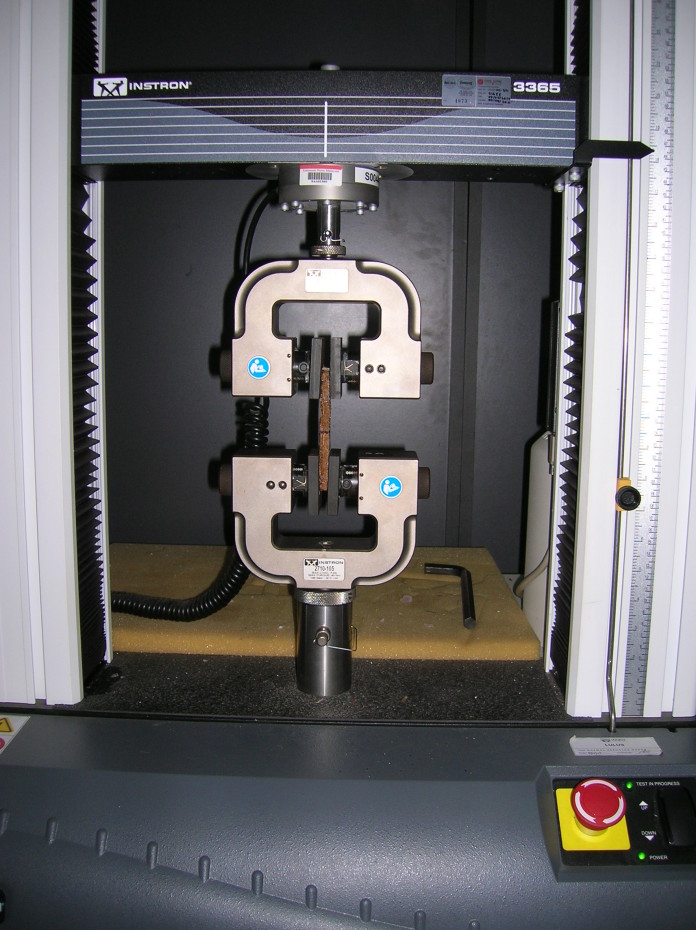

Universal testing machines

There are many types of testing machines. The most common are universal testing machines, which test materials in tension, compression or bending. There are two classes of testing machines, electromechanical and hydraulic. The electromechanical machine uses an electric motor, gear reduction system and one, two or four screws to move the crosshead up or down. A range of crosshead speeds can be achieved by changing the speed of the motor through the software control. A microprocessor based closed-loop servo system can be implemented to accurately control the speed of the crosshead. The main components of the universal testing machine are:

- actuator,

- attachment kit and

- measuring and safety devices