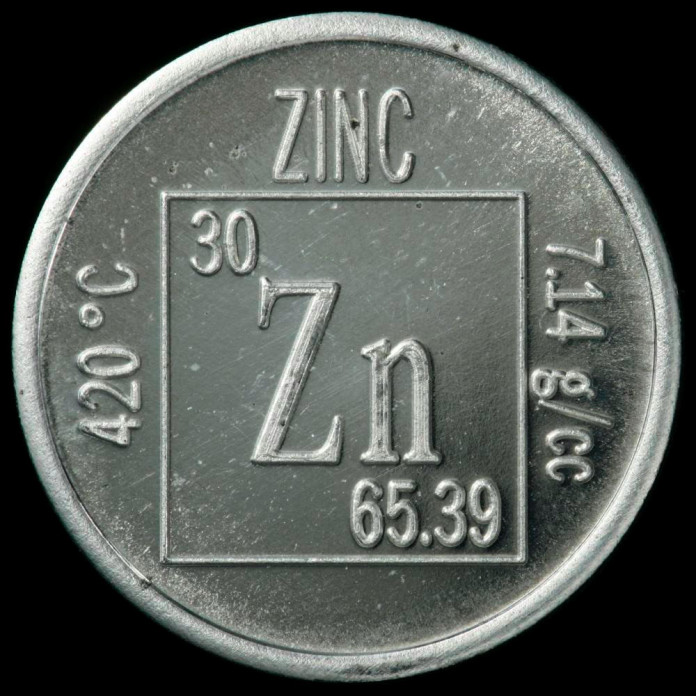

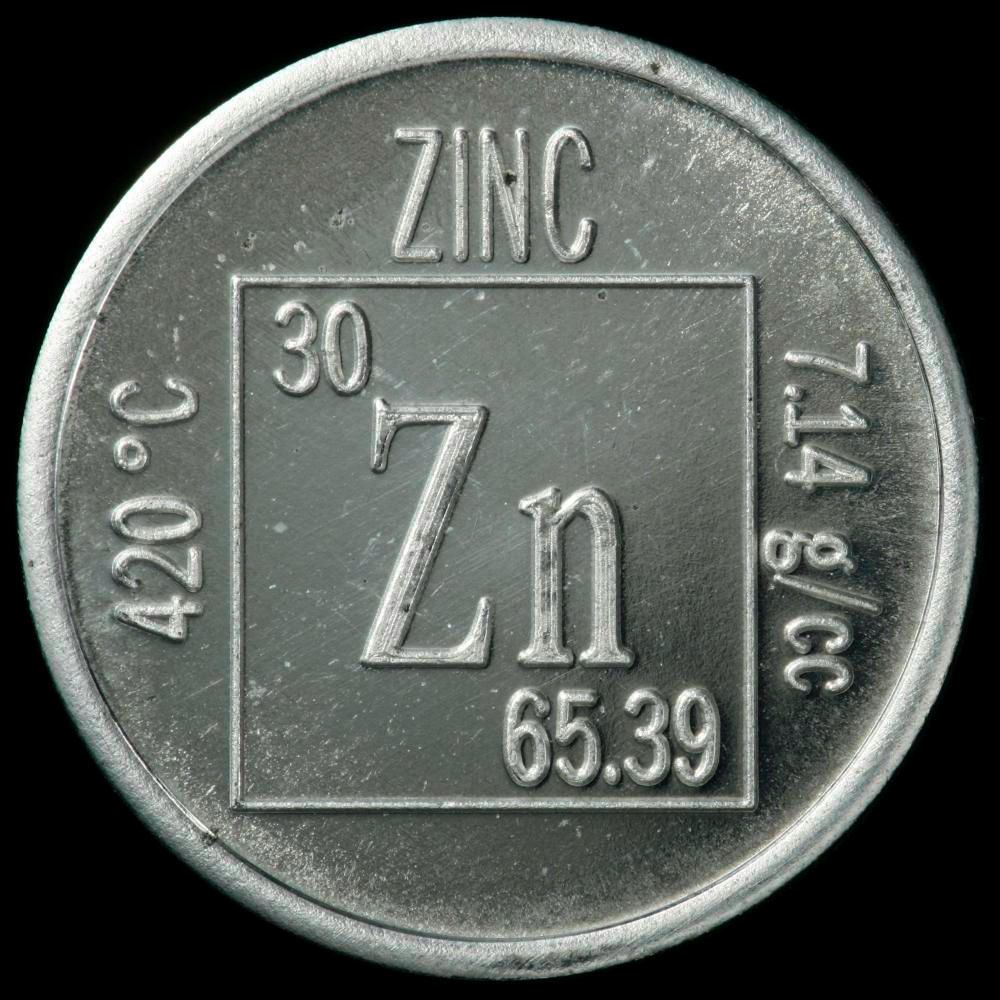

ZINC

Zinc is bluish grey in color and is obtained from common ores of zinc are zinc blende (ZnS), zincite (ZnO), calamine (ZnCO3). These ores are commonly available in Burma. The oxide is heated in an electric furnace where the zinc is liberated as vapor. The vapors are then cooled in condensers to get metallic zinc.

Zinc, in commerce also spelter, is a chemical element with symbol Znand atomic number 30. It is the first element of group 12 of the periodic table. In some respects zinc is chemically similar to magnesium: its ionis of similar size and its only common oxidation state is +2. Zinc is the 24th most abundant element in Earth’s crust and has five stableisotopes. The most common zinc ore is sphalerite (zinc blende), a zinc sulfide mineral. The largest mineable amounts are found in Australia, Asia, and the United States. Zinc production includes froth flotation of the ore, roasting, and final extraction using electricity (electrowinning).

Brass, which is an alloy of copper and zinc, has been used since at least the 10th century BC in Judea and by the 7th century BC in Ancient Greece. Zinc metal was not produced on a large scale until the 12th century in India and was unknown to Europe until the end of the 16th century. The mines of Rajasthan have given definite evidence of zinc production going back to the 6th century BC. To date, the oldest evidence of pure zinc comes from Zawar, in Rajasthan, as early as the 9th century AD when a distillation process was employed to make pure zinc. Alchemists burned zinc in air to form what they called “philosopher’s wool” or “white snow”.

The element was probably named by the alchemist Paracelsus after the German word Zinke. German chemist Andreas Sigismund Marggraf is credited with discovering pure metallic zinc in 1746. Work by Luigi Galvani and Alessandro Volta uncovered the electrochemical properties of zinc by 1800. Corrosion-resistant zinc plating of iron (hot-dip galvanizing) is the major application for zinc. Other applications are in batteries, small non-structural castings, and alloys, such as brass. A variety of zinc compounds are commonly used, such as zinc carbonateand zinc gluconate (as dietary supplements), zinc chloride (in deodorants), zinc pyrithione (anti-dandruff shampoos), zinc sulfide (in luminescent paints), and zinc methyl or zinc diethyl in the organic laboratory.

Zinc is an essential mineral perceived by the public today as being of “exceptional biologic and public health importance”, especially regarding prenatal and postnatal development. Zinc deficiencyaffects about two billion people in the developing world and is associated with many diseases. In children it causes growth retardation, delayed sexual maturation, infection susceptibility, anddiarrhea. Enzymes with a zinc atom in the reactive center are widespread in biochemistry, such as alcohol dehydrogenase in humans. Consumption of excess zinc can cause ataxia, lethargy and copper deficiency.

Properties

Zinc possesses specific gravity is 6.2 and low melting point of 480°C. Its tensile strength is 19 to 25 MPa. It becomes brittle at 200°C and can be powdered at this temperature. It possesses high resistance to corrosion. It can be readily worked and rolled into thin sheets or drawn into wires by heating it to 100-150°C.

Applications

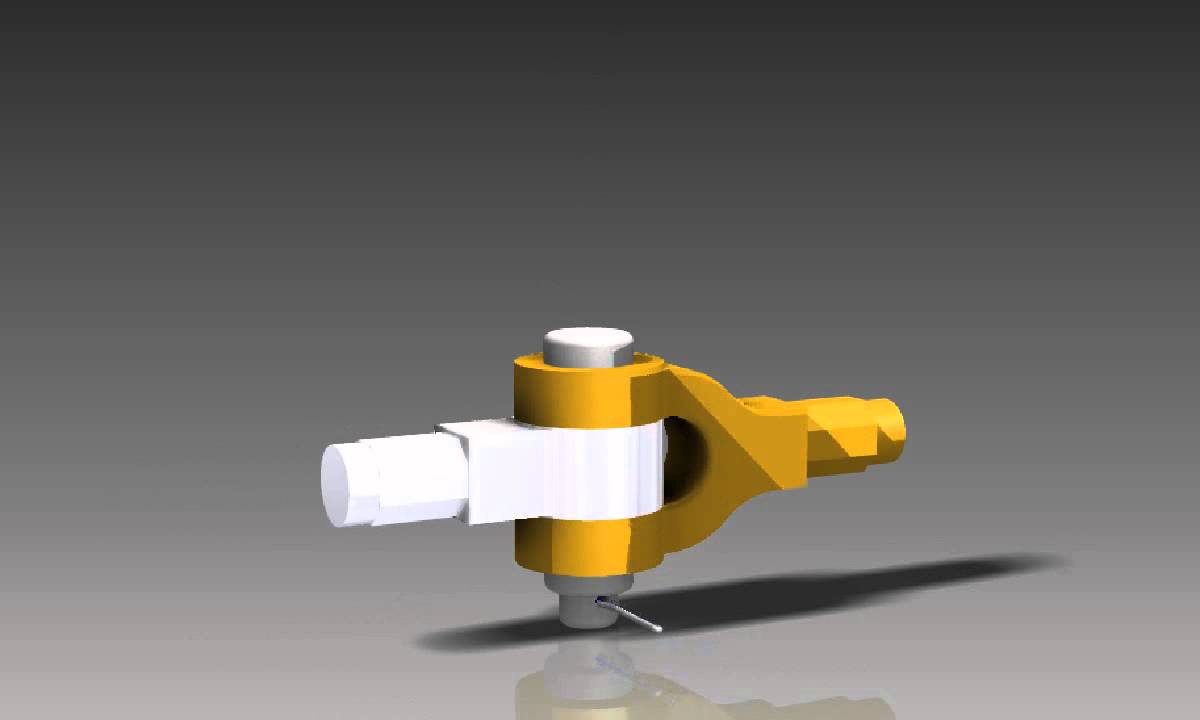

With regards to industrial applications, zinc is the fourth most utilized metal after iron, aluminium, and copper. Zinc is commonly used as a protective coating on iron and steel in the form of a galvanized or sprayed surface. It is used for generating electric cells and making brass and other alloys. The oxide of zinc is used as pigment in paints. Parts manufactured by zinc alloys include carburetors, fuel pumps, automobile parts, and so on.

Reference Introduction to basic Manufacturing Processes and Workshop Technology by Rajender Singh.

For engineering project visit this page regularly for know more things related project ideas. Click here to see Ideas of Projects. Engineers Gallery. All the Best!