INTRODUCTION:

Light dimming is based on adjusting the voltage which gets to the lamp. Light dimming has been possible for many decades by using adjustable power resistors and adjustable transformers. Those methods have been used in movie theatres, stages and other public places. The problem of those light controlling methods have been that they are big, expensive, have poor efficiency and they are hard to control from remote location. The power electronics have proceeded quickly since 1960. Between 1960-1970 thyristors and triacs came to market. Using those components it was quite easy to make small and inexpensive light dimmers which have good efficiency. Electronics controlling also made possible to make them easily controllable from remote location. This type of electronic light dimmers nowadays used in very many locations like homes, restaurants, conference rooms and in stage lighting.

To control of light dimmer we used a microcontroller to do the phase controlling. The microcontroller first read the dimmer setting value from the touch screen and according to that value it controls the light through some interface.

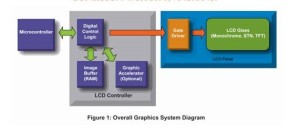

Graphics displays are gaining popularity in an increasing range of control and user interface applications in markets such as home automation, home appliance, medical and industrial. Examples include security systems, washing machines, cooking ranges, home blood pressure monitors, point-of-sale terminals, test and measurement units. Graphics displays enhance the user experience and provide detailed information with sharper images. Additionally, graphics displays enable technologies such as touch screen, leading to more effective and efficient interfaces to the applications.A typical graphics LCD system is shown in Figure 1. The system consists of a microcontroller, a LCD controller (digital-control logic, optional graphic accelerator, image buffer, gate driver), and a LCD glass.

The microcontroller normally creates, manipulates and renders graphic elements such as buttons, menus and images. If a graphic accelerator is present in the LCD controller, it provides hardware acceleration to some graphics elements and off-loads the microcontroller for other functions. The digital control logic serves as an image buffer arbiter and an electronic equivalent of picture tube for image display. A graphic LCD solution requires an image buffer to store a minimum of one image frame. Finally, the gate driver converts the digital to analog waveforms and drives the LCD glass. The gate driver is LCD glass dependent and changes based on the glass technology, size and resolution.

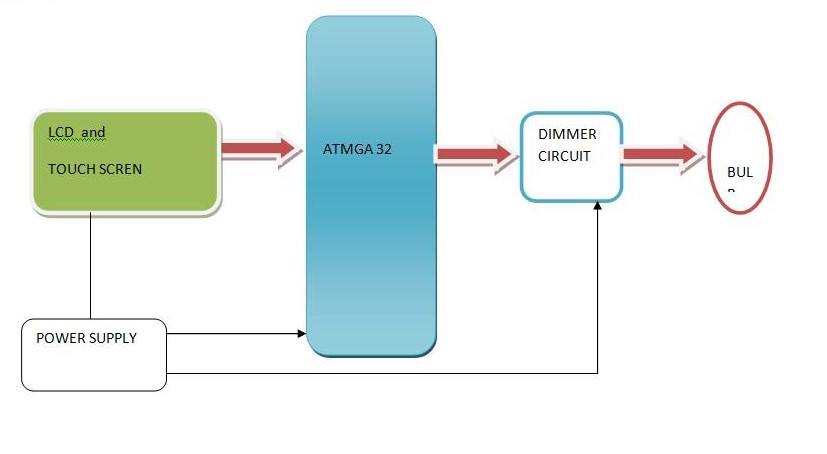

In current project a system is designed to control the light dimmer on the touch screen and graphics. This project demonstrates how touch screen can be easily interfaced to real world to control operation of complex systems like motor speed and direction. Below image shows the block diagram.

BLOCK DIAGRAM:

This block diagram shows a system that can be used control intensity of a brush Bulb. The current and mechanical feedback are optional depending on the application requirements.

HARDWARE COMPONENTS:

- At mega 1632

- touchscreen

- bulb

- gLCD

SOFTWARE:

- Code vision AVR IDE tool

- Embedded c programming

- Functionality of the above components

APPLICATIONS:

- Automation

- Automotive devices

- Remote application

- industrial application

SKILL SET:

- Functionality of all above components

- Embedded C programming

Post Comment

You must be logged in to post a comment.