INTRODUCTION:

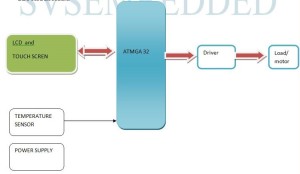

For any application in the industries there are many parameters to be handled. In this project we are concentrating on temperature sensor. This sensor is fixed at specified location, for our application to be performed. The Sensor gathers the values and sends the information to the microcontroller continuously. The microcontroller receives the values and sends the corresponding values to the Graphic LCD display. This is a cyclic process which performs till our requirement is done.

In this process as we have to reach our requirement we assign a certain Set-Points for the sensor to monitor the temperature (Ex; Temperature-39 degrees). If the Temperature Sensor crosses its specific Set-Point the microcontroller drives the Fan ‘ON’ and starts cooling to reach the set point. If the value from the sensor gets below the Set point, the microcontroller drives the heater ‘ON’ and starts the heating to reach the set point. This is a cyclic process. Touch screen is used to set the Set-Points for the sensor to monitor.

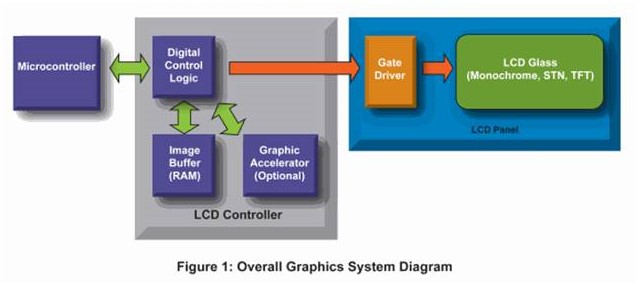

Graphics displays are gaining popularity in an increasing range of control and user interface applications in markets such as home automation, home appliance, medical and industrial. Examples include security systems, washing machines, cooking ranges, home blood pressure monitors, point-of-sale terminals, test and measurement units. Graphics displays enhance the user experience and provide detailed information with sharper images. Additionally, graphics displays enable technologies such as touch screen, leading to more effective and efficient interfaces to the applications.A typical graphics LCD system is shown in Figure 1. The system consists of a microcontroller, a LCD controller (digital-control logic, optional graphic accelerator, image buffer, gate driver), and a LCD glass.

The microcontroller normally creates, manipulates and renders graphic elements such as buttons, menus and images. If a graphic accelerator is present in the LCD controller, it provides hardware acceleration to some graphics elements and off-loads the microcontroller for other functions. The digital control logic serves as an image buffer arbiter and an electronic equivalent of picture tube for image display. A graphic LCD solution requires an image buffer to store a minimum of one image frame. Finally, the gate driver converts the digital to analog waveforms and drives the LCD glass. The gate driver is LCD glass dependent and changes based on the glass technology, size and resolution.

Applications for this are Industries with heavy parameters to handle, complicated areas where we can’t monitor the conditions manually; these are Now-a-days used in all kind of industrial and commercial complexes.

BLOCK DIAGRAM:

Post Comment

You must be logged in to post a comment.