ELECTRIC BRAKES

The electric current controlling the brake through the electromagnet is provided from a brake controller which provides the control current from the towing vehicle. There are different types of brake controllers on the market, each with their own advantages and disadvantages.

The current controlling the brakes from the towing vehicle is originating in the battery/alternator of the towing vehicle via the brake controller and then transferred via wiring through the electric brake pin in the trailer connector through the trailer wiring to the electromagnet and back through the trailer wiring to the trailer connector and to the towing vehicle chassis/frame through the ground pin in the trailer connector.

To minimize interference between vehicle lighting and brakes the circuits shall be as separated as possible.

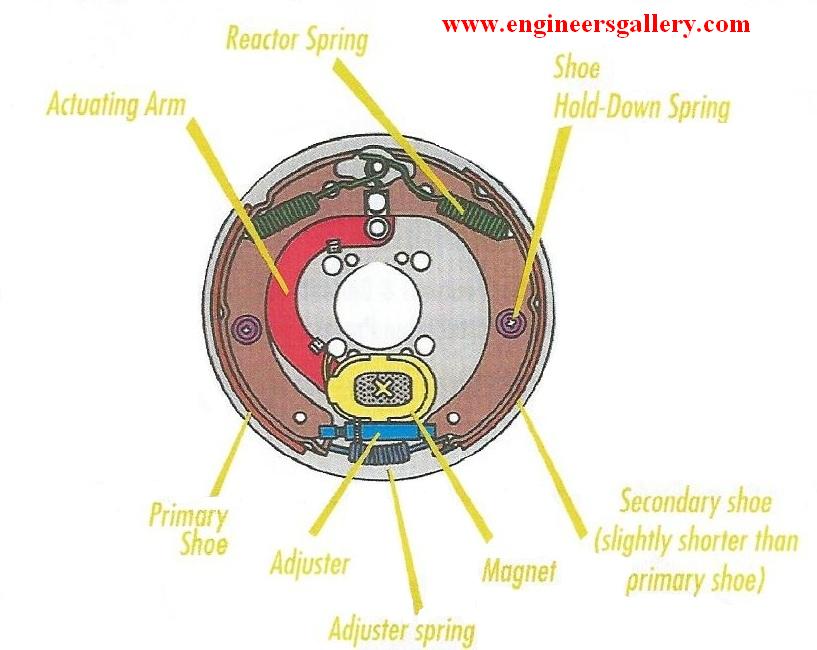

Take a look at the major parts that make up a brake assembly:

- Reactor Spring

- Actuating Arm

- Shoe Hold-Down Spring

- Primary Shoe

- Adjuster

- Adjuster Spring

- Magnet

- Secondary Shoe

The large center circle represents the hole through which the trailer spindle goes, so we can install the backing plate on the axle. The 4 smaller holes represent bolt holes which are used to bolt the backing plate onto the Brake Flange which sits behind the spindle.

How does electricity make this brake work?

The magnet in the backing plate has 2 conductor wires which tap directly into the trailer wiring. When electricity is on, it magnetizes the brake magnet. The magnet is attracted to the drum face. When it contacts this area, the friction causes it to rotate, which moves the actuating arm, and pushes the shoes out against the drum. Those shoes have a special brake pad material on them that resists the heat caused by that friction. When the shoes press against the inside of the drum, they prevent the hub, and consequently the wheel that’s touching the ground from spinning.

How does the electricity get to the trailer brakes? Where does it come from? How do we know which brake to use?

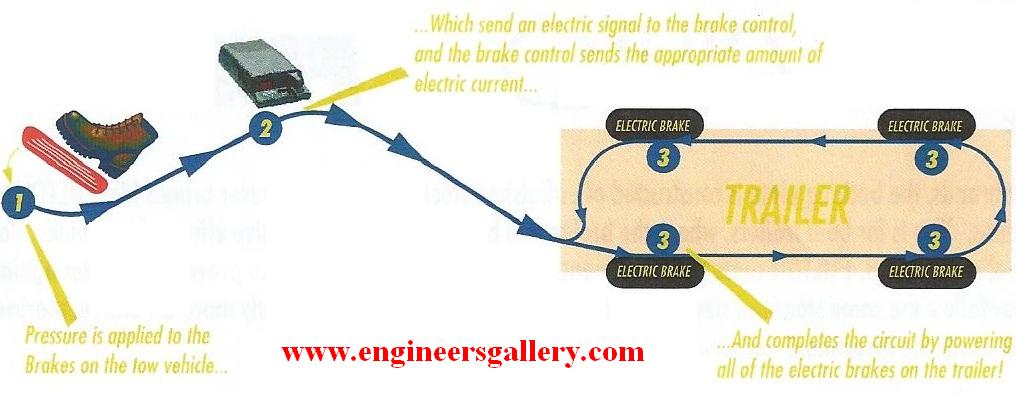

Here’s how it works: An electrical connection on the trailer plugs into the connector on the vehicle. There are electrical wires running from the trailer connector back to each brake on the axle, as well as to the trailer lights, to create a complete circuit. When the driver steps on the brakes it sends a current to the brake control in the vehicle. The brake control then sends a current back to the trailer to activate the brakes. Here’s what that looks like:

Why we should prefer Electric Brake?

Electric drum brakes are an extremely efficient and reliable braking system that require minimum maintenance.

They provide smooth efficient braking when operated by a vehicle mounted controller, which also provides the ability for the driver to manually apply the trailer brakes independent of the tow vehicle braking system. They are available both with and without park brake actuation and when used on trailers over 2000 kg gross tare mass (GTM) can be activated in a break away situation to conform with the Australian Design Rule requirements.

Possible electrical fault situations

Kirchhoff’s circuit laws are the basics for how to understand problems with the electrics. Electrical faults involving brakes can range from annoying to dangerous so it’s important to really get it working right.

When tracing faults it’s important to try to see all symptoms, since that can lead to a component that is common for all parts. And one component that really is taking a beating in most trailer electrical wiring is the ground pin of the connector since it has to handle all return current from the trailer to the towing vehicle.

Related Articles

Braking System and Its Classification, Application, Advantages and Disadvantages

A few symptoms that may occur on the trailer.

- Interference is known as ‘pulsating brakes’ which may occur when braking while also having the turn indicator flashing. There are different ways to minimize this problem, and it ranges from using a special pulse preventer to having a separate electric brake trailer connector with a brake circuit completely separated from the rest of the trailer wiring. Be aware that if you do a completely separate wiring the brake ground must be separated from the lighting ground. That includes the breakaway protection circuits and battery. (Think of what Kirchhoff’s circuit laws says).

- Lights on the trailer changing in proportion to the brake force applied.

- Brakes that actuates when some trailer lights are turned on. Watch out for this because the brakes may only be slightly dragging as soon as the position lights are on and that can result in unnecessary wear and overheated brakes.

Reference Wikipedia, hitchweb

Post Comment

You must be logged in to post a comment.