BEARING STRESS

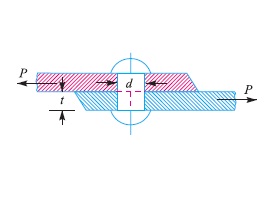

A localised compressive stress at the surface of contact between two members of a machine part, that are relatively at rest is known as bearing stress or crushing stress. The bearing stress is taken into account in the design of riveted joints, cotter joints, knuckle joints, etc. Let us consider a riveted joint subjected to a load P as shown in Fig. 4.9. In such a case, the bearing stress or crushing stress (stress at the surface of contact between the rivet and a plate),

.’. σb (or σc) =P/d*t*n

where, d = Diameter of the rivet,

t = Thickness of the plate,

d.t = Projected area of the rivet, and

n = Number of rivets per pitch length in bearing or crushing.

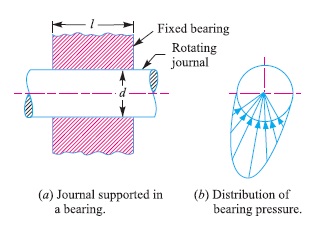

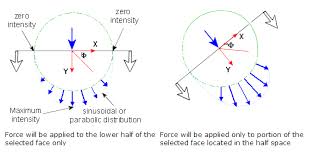

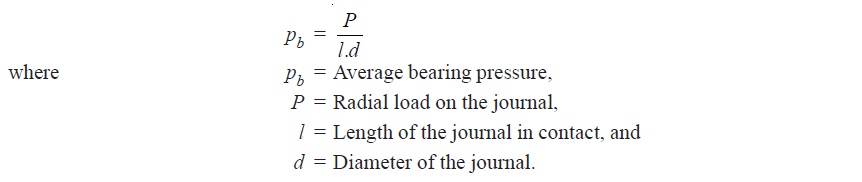

It may be noted that the local compression which exists at the surface of contact between two members of a machine part that are in relative motion, is called bearing pressure (not the bearing stress). This term is commonly used in the design of a journal supported in a bearing, pins for levers, crank pins, clutch lining, etc. Let us consider a journal rotating in a fixed bearing as shown in Fig. 4.10 (a). The journal exerts a bearing pressure on the curved surfaces of the brasses immediately below it. The distribution of this bearing pressure will not be uniform, but it will be in accordance with the shape of the surfaces in contact and deformation characteristics of the two materials. The distribution of bearing pressure will be similar to that as shown in Fig. 4.10 (b). Since the actual bearing pressure is difficult to determine, therefore the average bearing pressure is usually calculated by dividing the load to the projected area of the curved surfaces in contact. Thus, the average bearing pressure for a journal supported in a bearing is given by,

Reference

A Textbook of Machine Design by R.S.Khurmi and J.K.Gupta

Post Comment

You must be logged in to post a comment.