Knuckle Joint :

A knuckle joint is a mechanical joint used to connect two rods which are under a tensile load, when there is a requirement of small amount of flexibility, or angular moment is necessary. There is always axial or linear line of action of load.

A knuckle joint is used to connect two rods which are under the action of tensile loads. However, if the joint is guided, the rods may support a compressive load. A knuckle joint may be readily disconnected for adjustments or repairs.

Its use may be found in the link of a cycle chain, tie rod joint for roof truss, valve rod joint with eccentric rod, pump rod joint, tension link in bridge structure and lever and rod connections of various types.

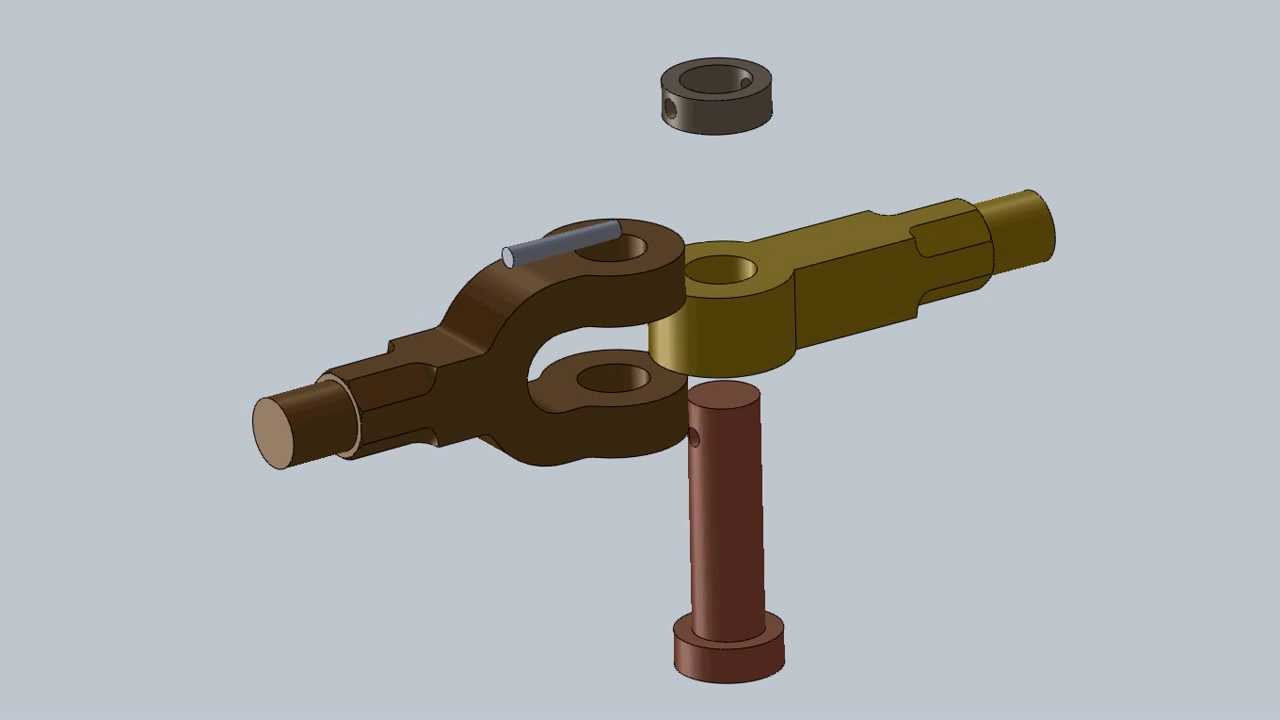

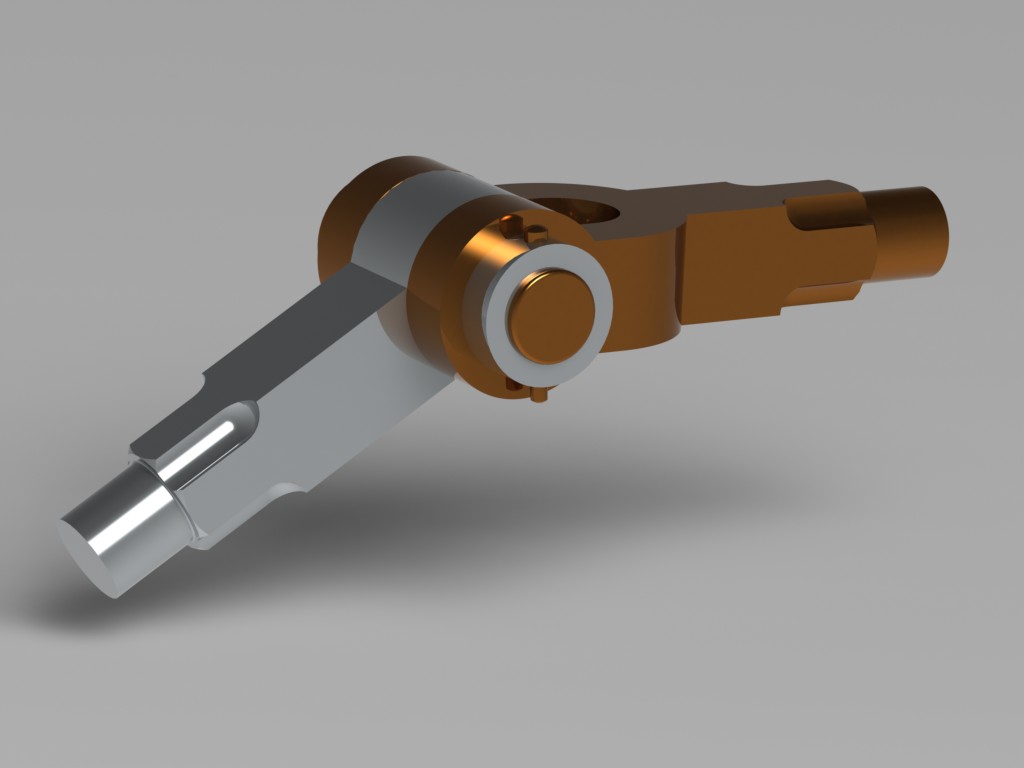

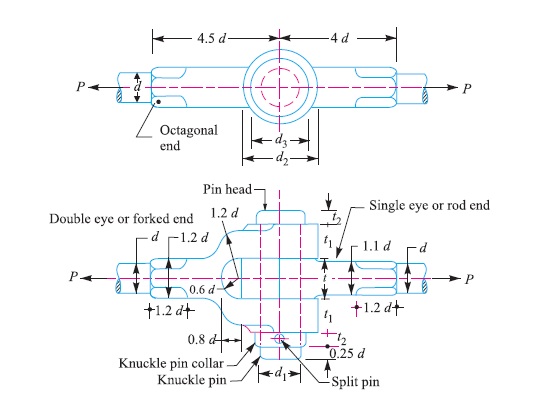

In knuckle joint (the two views of which are shown in Fig. 3), one end of one of the rods is made into an eye and the end of the other rod is formed into a fork with an eye in each of the fork leg. The knuckle pin passes through both the eye hole and the fork holes and may be secured by means of a collar and taper pin or spilt pin. The knuckle pin may be prevented from rotating in the fork by means of a small stop, pin, peg or snug. In order to get a better quality of joint, the sides of the fork and eye are machined, the hole is accurately drilled and pin turned. The material used for the joint may be steel or wrought iron.

Dimensions of Various Parts of the Knuckle Joint

The dimensions of various parts of the knuckle joint are fixed by empirical relations as given below. It may be noted that all the parts should be made of the same material i.e. mild steel or wrought iron.

If d is the diameter of rod, then diameter of pin,

d1 = d

Outer diameter of eye,

d2 = 2 d

Diameter of knuckle pin head and collar,

d3 = 1.5 d

Thickness of single eye or rod end,

t = 1.25 d

Thickness of fork, t1 = 0.75 d

Thickness of pin head, t2 = 0.5 d

Other dimensions of the joint are shown in Fig.

[button color="" size="20" type="3d" target="" link="https://www.engineersgallery.com/design-of-knuckle-joint/"]Design of knuckle joint[/button]

[button color="" size="" type="3d" target="" link="https://www.engineersgallery.com/methods-of-failure-of-knuckle-joint/"]Methods of Failure of Knuckle Joint[/button]

Reference A Textbook of a Machine Design by R.S. Khurmi and J.K. Gupta

Post Comment

You must be logged in to post a comment.