AIR CONDITIONING PROJECT DEVELOPMENT

Basic Steps in Development

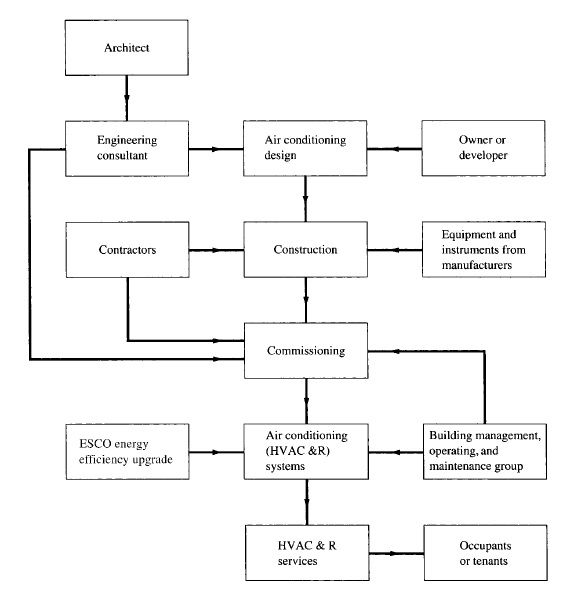

The basic steps in the development and use of a large air conditioning system are the design, construction, commissioning, operation, energy efficiency upgrading, and maintenance. Figure 1. is a diagram which outlines the relationship between these steps and the parties involved. The owner sets the criteria and the requirements. Design professionals in mechanical engineering consulting firms design the air conditioning system and prepare the design documents. Manufacturers supply the equipment, instruments, and materials. Contractors install and construct the air conditioning system. After construction, the air conditioning system is commissioned by a team, and then it is handed over to the operation and maintenance group of the property management for daily operation. Following a certain period of operation, an energy service company (ESCO) may often be required to upgrade the energy efficiency of the HVAC&R system (energy retrofit).

Design-Bid and Design-Build

There are two types of project development: design-bid and design-build. A design-bid project separates the design and installation responsibilities, whereas in a design-build project, engineering is done by the installing contractor. Some reasons for a design-build are that the project is too small to retain an engineering consultant, or that there is insufficient time to go through the normal design-bid procedures.

According to Bengard (1999), the main advantages of design-build include established firm price early, single-source responsibility, accelerated project delivery, and performance guarantees. The market has experienced nearly 300 percent domestic growth since 1986.

The Goal—An Environmentally Friendlier, Energy-Efficient, and Cost-Effective HVAC&R System

The goal is to provide an HVAC&R system which is environmentally friendlier, energy-efficient, and cost-effective as follows:

- Effectively control indoor environmental parameters, usually to keep temperature and humidity

within required limits. - Provide an adequate amount of outdoor ventilation air and an acceptable indoor air quality.

- Use energy-efficient equipment and HVAC&R systems.

- Minimize ozone depletion and the global warming effect.

- Select cost-effective components and systems.

- Ensure proper maintenance, easy after-hour access, and necessary fire protection and smoke control

systems.

Major HVAC&R Problems

In Coad’s paper (1985), a study by Wagner-Hohn-Ingles Inc. revealed that many large new buildings constructed in the early 1980s in the United States suffer from complaints and major defects. High on the list of these problems is the HVAC&R system. The major problems are these:

1. Poor indoor air quality (IAQ)—sick building syndrome. Poor indoor air quality causes the sick building syndrome. The National Institute of Occupational Safety and Health (NIOSH) in 1990 reported that between 1971 and 1988, 529 field investigations found that lack of outdoor air, improper use, and poor operation and maintenance of HVAC&R systems were responsible for more than one-half of sick building syndrome incidents. Field investigations found that 20 to 30 percent of the buildings had poor-air-quality problems. Sick building syndrome is covered in detail in Chap. 4.

2. Updated technology. In recent years, there has been a rapid change in the technology of air conditioning. Various types of VAV systems, air and water economizer, heat recovery, thermal storage, desiccant dehumidification, variable-speed drives, and DDC devices have become more effective and more advanced for energy efficiency. Many HVAC&R designers and operators are not properly equipped to apply and use these systems. Unfortunately, these sophisticated systems are managed, constructed, and operated under the same budget and schedule constraints as the less sophisticated systems. After years of operation, most HVAC&R equipment and controls need to be upgraded for energy efficiency.

3. Insufficient communication between design professionals, construction groups, and operators. Effective operation requires a knowledgeable operator to make adjustments if necessary. The operator will operate the system at his or her level of understanding. If adequate operating and maintenance documents are not provided by the designer and the contractor for the operator, the HVAC&R system may not be operated according to the designer’s intentions.

4. Overlooked commissioning. Commissioning means testing and balancing all systems, functional testing and adjusting of components and the integrated system, and adjusting and tuning the direct digital controls. An air conditioning system is different from the manufacturing products having models and prototypes. All the defects and errors of the prototypes can be checked and corrected during their individual tests, but the more complicated HVAC&R system, as constructed and installed, is the end product. Therefore, proper commissioning, which permits the system to perform as specified in the design documents, is extremely important. Unfortunately, the specifications seldom clearly designate competent technicians for the responsibility of commissioning the entire integrated system. Commissioning is covered in detail in Chap. 32.

5. Reluctant to try innovative approaches. In addition to Coad’s paper, a survey was conducted by the American Consulting Engineers Council (ACEC) in 1995. For the 985 engineering firms that responded out of about 5500 firms total, there were 522 legal claims filed against them, 49 percent of suits resolved without payment. Among the 522 legal claims, 9 percent were filed against mechanical engineering firms. Fifty-two percent of 1995 legal claims were filed by owners, and 13 percent were filed by contractors or subcontractors.

Because of the legal claims, insurance companies discourage innovation, and engineering consulting firms are reluctant to try innovative techniques. Twenty-one percent of these firms said they were very much reluctant, 61 percent said they were somewhat affected, and 25 percent said they were a little affected. Support and encouragement must be given to engineering firms for carefully developed innovative approaches to projects. In addition to the ASHRAE Technology Awards, more HVAC&R innovative awards should be established in large cities in the United States to promote innovative approaches.

Copied from HANDBOOK OF AIR CONDITIONING AND REFRIGERATION by Shan K. Wang Second Edition McGraw-Hill

1 comment