COMPUTER AIDED MANUFACTURING (CAM)

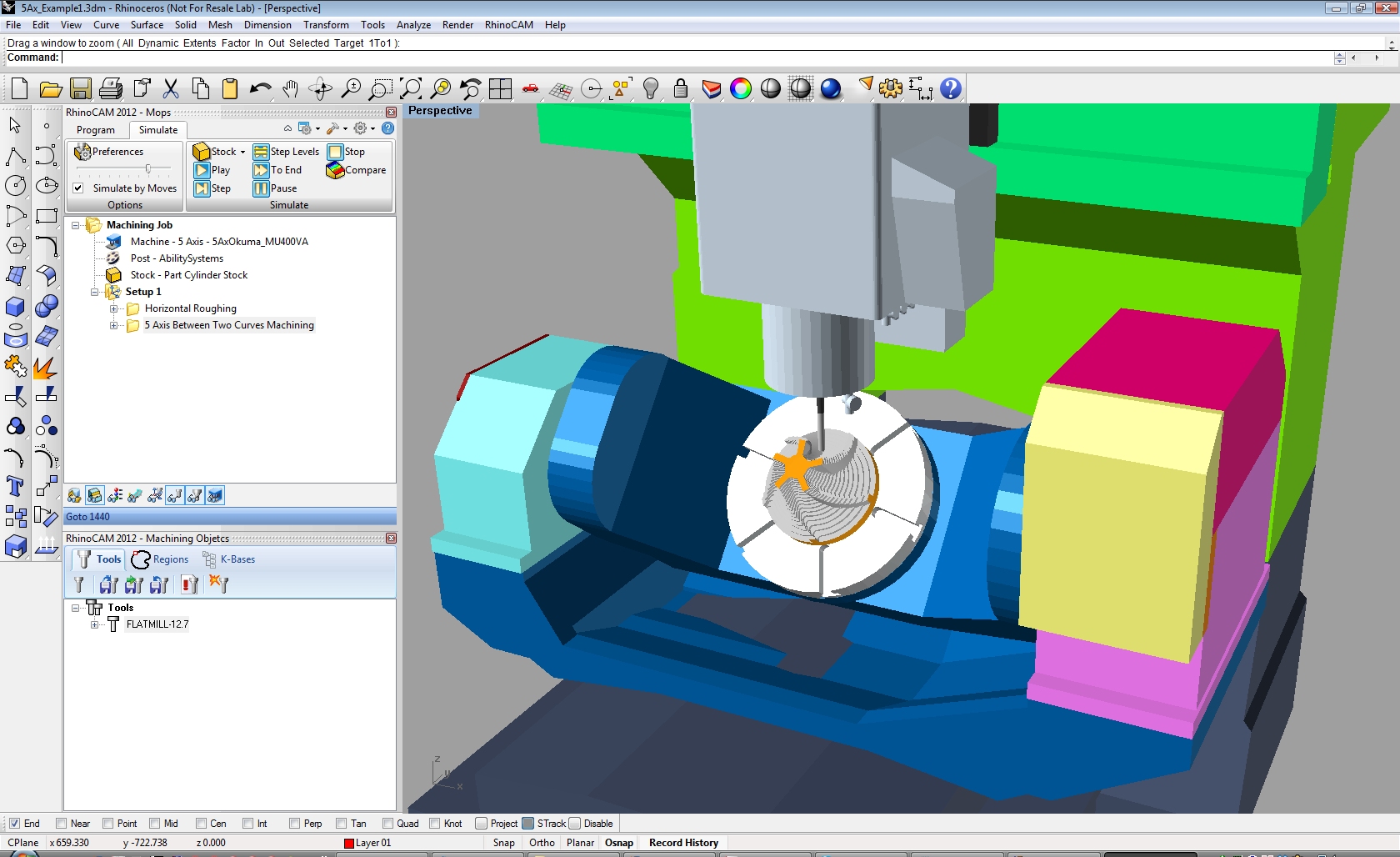

The computer aided manufacturing implies manufacturing itself, aided or controlled by computers. In a wider sense, it denotes all the activities in the manufacturing environment like use of computers in inventory control, project management, material requirement planning, data acquisition, testing and quality control. Improved reliability in view of the better manufacturing methods and controls at the manufacturing stage, the products thus manufactured as well as of the manufacturing system would be highly reliable. Since most of the components of a CAM system would include integrated diagnostics and monitoring facilities, they would require less maintenance compared to the conventional manufacturing methods. Because of the Computer Numerical Control (CNC) machines used in production and the part programs being made by the stored geometry from the design stage, the scrap level would be reduced to the minimum possible and almost no rework would be necessary. Since all the information and controlling functions are attempted with the help of the computer, a better management control on the manufacturing activity is possible.

All the above advantages when properly translated, would mean a lower total cost and consequently, higher final earnings. Therefore any manufacturing activity in a production unit (job shop production or mass scale manufacture) can get the benefits of Computer Aided Manufacturing. However, better results can be obtained when the design and manufacturing activities are properly integrated. Also, when there is a large variety of products or minor changes required in the existing production programme, CAM can easily manage the necessary changes or alterations.

Following are the main advantages of using CAM.

1. Greater design freedom

Any changes that are required in design can be incorporated at any design stage without worrying about any delays, since there would hardly be any in an integrated CAM environment.

2. Increased productivity

In view of the fact that the total manufacturing activity is completely organized through the computer, it would be possible to increase the productivity of the plant.

3. Greater operating flexibility

CAM enhances the flexibility in manufacturing methods and changing of product lines.

4. Shorter lead time

Lead times in manufacturing would be greatly reduced. The integration of CAD and CAM systems is called Computer Integrated Manufacturing (CIM) system. The role of computer in manufacturing may be in two major groups namely computer monitoring and control of the manufacturing process and manufacturing support applications, which deal essentially with the preparations for act of manufacturing and post manufacture operations. Computers are used in controlling machine tools and other material handling equipments.

Reference Introduction to basic Manufacturing Processes and Workshop Technology by Rajender Singh.

For engineering project visit this page regularly for know more things related project ideas. Click here to see Ideas of Projects.

Post Comment

You must be logged in to post a comment.