FELLING, CONVERSION AND SEASONING OF WOOD

Cutting of living or standing trees to obtain timber is called felling of trees. Trees are cut at appropriate time. The best time for sawing the tree is immediately after the tree has achieved its full growth or maturity age so that the maximum quantity and best quality of wood can be obtained. If an immature tree is cut, it will carry a lot of sapwood which may not be much useful for the carpentry work. Contrary to this, if the tree is allowed to stand for long after attaining the maturity the most valuable part of timber will be subjected to decay. Therefore enough care must be taken to see that felling is accomplished only at the appropriate time.

The proper time of cutting of a tree depends largely on its age and season of the year. Cutting of trees for getting wood for use is done generally in mid-summer or mid-winter because the sap of the tree is at rest during this period and therefore, the chances of any decay of useful wood are minimized. The time taken for a tree to mature depends whether it is softwood or hardwood. The softwood tree will mature after 80 to 100 years whereas hardwood will take more time between 130 and 200 years for getting mature. After cutting the trees from bottom, the branches are removed from it and form of log is obtained. The process of sawing wooden logs into useful sizes and shapes (boards, planks squares and other planes section and sizes etc.) for market or commercial requirements is known as conversion. Conversion is carried over prior to seasoning by two methods namely plain, through, through sawn process and quarter and rift sawn process. Plain sections of wood may likely to warp and hence cannot be used for quality work. Quarter sawing almost eliminates the chances of warping. Quarter sawn sections are used as quality wood in cabinet making, decoration and framework. Plantation of new trees is also essential and that should be carried out form time to time. Conversion means sawing of timber logs into different commercial sizes. A notable feature in conversion is to provide an adequate allowance for shrinkage that takes place during seasoning of sawn or converted wood. The shrinkage of wood usually varies between 3.2 mm to 6.4 mm, according to the type of wood and its time of cutting. The three methods of conversion commonly adopted are discussed as under.

The first method is called as flat or ordinary cutting which is the simplest procedure of sawing but the cut sections are likely to warp. Therefore, the wood cut through this procedure cannot be called as quality work. In this method, the timber log is cut into a number of boards by taking various parallel saw cuts into the suitable forms.

The second method is known as tangential cutting in which cutting takes place in such a way that the widths of the boards are tangential to the annual rings. The timber cut by this method is seasoned quickly and cutting wastage is also less but it may warp like flat sawn wood.

The third procedure is known as quarter or radial sawing in which the timber logs are sawn so that the width of the sawn boards falls along the medulary rays which mean they run across the section of the log. The normal defect of warping is almost eliminated by this procedure of sawing and the timber is very suitable for all sorts of wood work involving cabinet-making, decoration and framework. Trees are converted into the following useful marketable forms such as posts (square pieces of timber 175-300 mm wide or round pieces of 175-300 mm in diameter), deals (225 mm wide and about 100 mm thick parallel side pieces), planks (50 to 100 mm thick, 275-300 mm wide and 3 to 7 meters long) and boards or battens (25 to 50 mm thick and 125 to 175 mm wide). Sizes of timber (Kail, Deodar etc.) available in the market for building construction purposes are 10′ × 10″ × 5″ or 12′ × 10″ × 5″ or 10′ × 8″ × 5″ or 10′ × 8″ × 4″ etc.

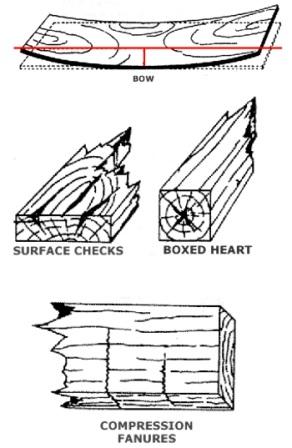

Seasoning of wood is the reduction of the moisture or sap content of it to the point where, under normal conditions of use, no further drying out will take place. The main objective of seasoning is to reduce the unwanted amount of moisture from the timber. As the moisture contained in the cell walls evaporates, shrinkage of the timber takes place which is greatest along the growth rings. Certain other defects such as shaking and warping may develop during seasoning. Therefore for these reasons green or unseasoned timber should not used for any work but for rough work. Once the timber is seasoned before use, it will not shrink, twist or swell during its further use. Need for seasoning of timber before its use is necessary in order to achieve the required moisture content, to reduce fungi decay, to minimize attack of insects, to increase strength of wood and for reduction of wood warpage Seasoning is classified into two categories namely natural seasoning and artificial seasoning. Natural seasoning is carried out generally in air, or in water or in smoke. Air seasoning is the oldest method of drying timber and it depends entirely upon the free flow of air around the wood to evaporate moisture. A timber stack in a shade for air seasoning.

In water seasoning, the timber balks are immersed in water for 15-20 days. During period, the flowing water drives away the sap pf wood it. Timber is then taken out and dried in open air for about a month. Water seasoning takes less time than air seasoning, but the strength of wood is reduced. However by water seasoning, the timber is less liable to warp, crack and distort. This method of seasoning is highly suitable for seasoning green wood full of sap. This seasoning process renders timber less liable to rot decay. In smoke seasoning, the wood is dried by using the smoke of rough burning timber and waste leaves. The smoke seasoning is used for woods in boats. Artificial seasoning is controlled by application of both heat and humidity which enables to reduce the moisture content quickly and accurately. After artificial seasoning the wood becomes harder, whereas in natural seasoning the wood becomes soft. Kiln seasoning is an important type of artificial seasoning in which the timber is seasoned by the use of a forced draught of warm air in which brings about a rapid reduction in moisture content. Copied from Introduction to Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.