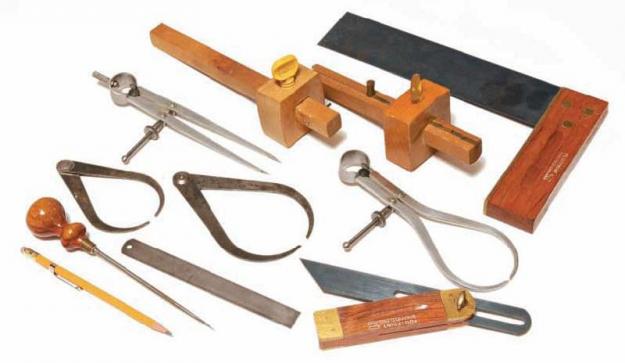

Marking and Measuring Tools Used In Carpentary Shop

Marking in order to make wooden components of the required size or the marking of exact dimensions on the wooden piece is essential to produce quality jobs. A number of marking and measuring instruments namely Rules, Try Square, Combination Set, Bevel Gauge, Marking Gauge, Mortise Gauge, Cutting Gauge, Spirit Level, Trammel and Compass are commonly used for this purpose. Some of commonly used marking and measuring instruments are discussed as in chapter of fitting and sheet metal work under.

Rules

Rules are straight edge of wood or steel engraved in millimeters- centimeters or in inches-foot or in both. Theses are used to mark, measure the length, widths and thicknesses of wood part. Steel rule, folding rule and flexible steel rule. These rules are available in different sizes and designs. Metallic taps bearing sizes 6″, 12″ or 18″ are used for general measuring work. For example 24″ folding tape and 5″ or 6″ steel tape are used measuring larger dimensions. An important small instrument in any shop is a good quality straight-edge bench rules. These rules are manufactured of either metal or wood. They are used to check for straightness and to measure and mark straight lines. The bench rule may be graduated in inches, millimeters or both. The length of the bench rule may be 12″, 24″ or 36″. The 36″ rule is called yardstick. Another type of rule is folding two-foot rule which is more convenient than a straight 24″ rule. The zigzag rules are used to measure longer stock when exact measurements are not so important. One of These rules, when open may be of usually 6 or 8 feet long. The push pull steel tape or tape rule is a very compact metal rule that comes in lengths of 6, 8 or 10 feet. There is a hook at the end to slip over the edge of the bold. It is flexible to bends easily and can measure curved surfaces too. It is very good for measuring the inside depth of the hole of components also.

Try Square

Try square is generally utilized for measuring and checking of squareness, perpendicularity, dimensions, testing of finish of planned surfaces and drawing parallel and perpendicular lines. The steel blade and metallic or wooden handle of try square are at right angles to each other. Try square is used for testing the level, edge and squareness of the wooden surfaces. It is also used for marking lines across the face or edge of wooden block. There are graduations along the blade of the rule that are used for measuring and marking purposes on the wooden jobs. The blade of try square is made of hard tempered steel of non rusting kind. It is seldom used for hammering work.

Combination Set

Combination set is frequently used in the carpentry shop for different kind of measurements. It consists of blade and a head. The blade has a groove cut along its length so that it can slide into the head. One side of the head makes a 90° angle with the blade and the other side a 45° angle. It can be making, measuring and setting different angle. It also acts as a try square, angle gauge to set 45° angles, a depth gauge and level checking tool.

Bevel Gauge

Bevel gauge is also known as an adjustable bevel which is mainly used for marking, measuring and inspecting angles from 0 to 180 degree. Its blade can be adjusted and set to any desired angle.

Marking Gauge

The marking gauge is made of wood which is important tool utilized to make lines at a uniform distance from the edge of a board or piece of work and is used principally when preparing wooden components to size before jointing. The marking gauge like the mortise gauge and cutting gauge in use should be positioned correctly. For marking purposes, the gauge is drawn towards the body or pushed away from it but in either case, if the spur does not trail. It will tend to jump and run with the grain. Thumb screw of the marking gauge locks the stock at any position. The spur made of hardened steel should be ground to a fine point. And for ease of working, it should not project too far from the face of the stem. It is commonly used to mark or scribe line parallel to and at any desired distance from a finished edge or face of a surface.

Cutting Gauge

Cutting gauge is similar in construction to the marking gauge but having a knife in place of the marking pin or spur. It can be utilized for gauging and marking deep lines across the grain of wood in thicker sections. It is also used for setting out the shoulder-lines of lap dovetails and similar joints, as well as for trimming veneers parallel to the edge of surface before laying a cross-band. Cross banding is the laying of a strip of cross-grained veneer around the edge of a surface for example the edges of a table top, box lid or drawer front. This gauge is very useful for making very small rebates to receive inlay lines and may be used in place of marking gauge. Inlay lines are thin strips of wood which can be glued into a rebate cut around the edge of a veneered surface.

Mortise Gauge

This is an improved form of marking gauge which consists of main components as fixed pin, sliding pin, brass strip, stem, rose wood stock and thumb screw. The fixed pin of the gauge is attached to a short brass strip which is screwed to the stem. The sliding pin is fixed to a long brass strip or slider is adjusted by means of a thumbscrew. The threaded portion of which engages in a cylindrical nut which is embedded in the stem. The stock is locked in position by a metal set screw. This gauge is used for marking out of the parallel sides of a mortises or tenons and other similar joints. Copied from Basic of Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.