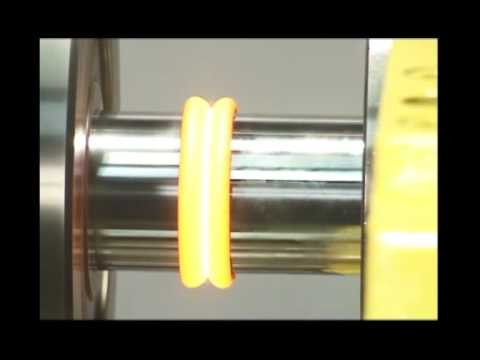

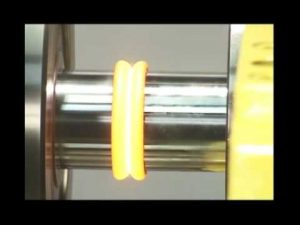

Friction Welding

In this process, the heat for welding is obtained from mechanically induced sliding motion between rubbing surfaces of work-pieces as shown in Fig. In friction welding, one part is firmly held while the other (usually cylindrical) is rotated under simultaneous application of axial pressure. As these parts are brought to rub against each other under pressure, they get heated due to friction. When the desired forging temperature is attained, the rotation is stopped and the axial pressure is increased to obtain forging action and hence welded joint.

Most of the metals and their dissimilar combinations such as aluminium and titanium, copper and steel, aluminium and steel etc. can be welded using friction welding. Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.