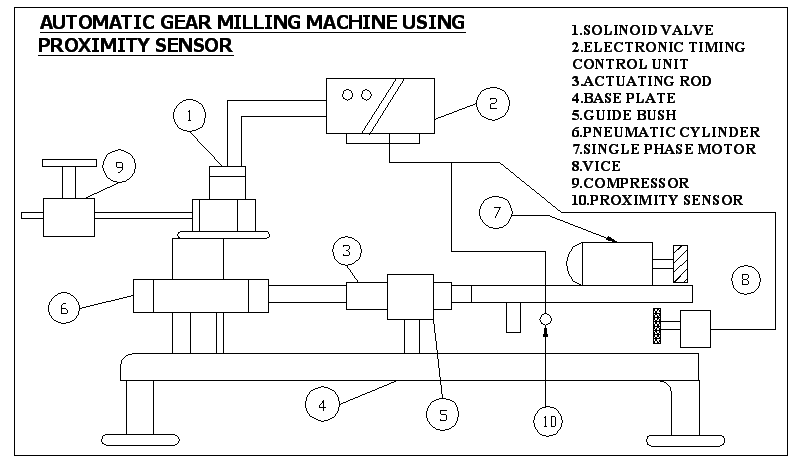

AUTOMATIC GEAR MILLING MACHINE USING PROXIMITY SENSOR

The Gera milling machine is a metal milling machine tool designed to cut/grind metal by applying pneumatic pressure. The machine is exclusively intended for mass production and they represent the fasten and more efficient way to cut a metal. The slow speed operation is occurs in a milling operation. This machine is a multipurpose machine.

Hacksaws are used to cut thin and soft metals. The milling shaft is used to milling operation by replacing the hacksaw frame. The operation of the unit is simplified to a few simple operations involving a cylinder block and piston arrangement.

There are numerous types of milling machines in Engineering field, which are used to fulfill the requirements. We are interested to introduce pneumatic system in especially in milling machine and also milling operation. The main function of Pneumatic milling is to cut thin and soft metals by pneumatic power.

INTRODUCTION

The word ‘pneuma’ comes from Greek and means breather wind. The word pneumatics is the study of air movement and its phenomena is derived from the word pneuma. Today pneumatics is mainly understood to means the application of air as a working medium in industry especially the driving and controlling of machines and equipment.

Pneumatics has for some considerable time between used for carrying out the simplest mechanical tasks in more recent times has played a more important role in the development of pneumatic technology for automation.

WORKING PRINCIPLE

Since pneumatic circuit plays a vital role in this device, it is very necessary to explain the working of this circuit.Initially starting with air compresses, its function is to compress air from a low inlet pressure (usually atmospheric) to a higher pressure level. This is an accomplished by reducing the volume of the air.

Air compressors are generally positive displacement units and are either of the reciprocating piston type or the rotary screw or rotary vane types. The air compressor used here is a typically small sized, two-stage compressor unit. It also consists of a compressed air tank, electric rotor and pulley drive, pressure controls and instruments for quick hook up and use. The stored air from compressor is passed through an air fitter where the compressed air is filtered from the fine dust particles. However, before the suction of air into compressor a filter process take place, but not sufficient to operate in the circuit here the filter is used. Then having a pressure regulator where the desired pressure to the operated is set. Here a variable pressure regulator is adopted.

Through a variety of direction control value are available, a hand operated solenoid Valve with control unit is applied. The solenoid valve used here is 5 ports, 3 positions. There are two exhaust ports, two outlet ports and one inlet port. In two extreme positions only the directions can be changed while the Centro ore is a neutral position and no physical changes are incurred.

The 2 outlet ports are connected to an actuator (Cylinder). The pneumatic activates is a double acting, single rod cylinder. The cylinder output is coupled to further purpose. The piston end has an air horning effect to prevent sudden thrust at extreme ends.

PRINCIPLES OF WORKING

- The compressed air from the compressor reaches the solenoid valve. The solenoid valve changes the direction of flow according to the signals from the timing device.

- The compressed air pass through the solenoid valve and it is admitted into the front end of the cylinder block. The air pushes the piston for the spring end milling stroke. At the end of the spring end milling stroke air from the solenoid valve reaches the rear end of the cylinder block.

- The pressure remains the same but the area is less due to the presence of piston rod. This exerts greater pressure on the piston, pushing it at a faster rate thus enabling faster return stroke.

- The stroke length of the piston can be changed by making suitable adjustment in the timer.

ADVANTAGES

- There is no need of giving feed during every cut due to the presence of weight.

- The milling/milling speed can be varied according to our needs by adjusting the timer.

- It is portable

- It does not have any Prime mover, like electric motor related to the unit.

- As the air is freely available, we can utilize the air to cut the metal and hence it is economical.

- Simple in construction than mechanical hacksaw and grinder

- It is a compact one

- Less Maintenance

LIMITATIONS

- Only smaller size and soft metal can be cut

- It is costlier than the mechanical hacksaw because of compressor unit.

- Less efficiency when compressed to mechanical device.

APPLICATIONS

1. Milling Applications

2. Chemical Industry

3. Plastics and rubber industries

4. Stone, Ceramic and glass industries

Post Comment

You must be logged in to post a comment.