Sheet Metal Bending

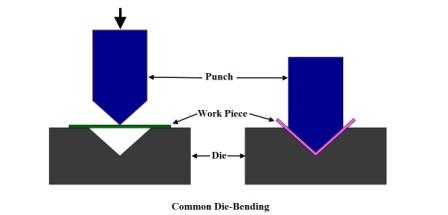

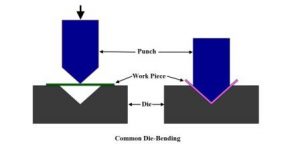

It is employed for bending into desired shapes various stock materials like sheets, rods, wires, bars, pipes, tubes and various structural shapes. Formed dies are used for bending the articles and the operation is usually performed in many stages. For bending in all sheet material are stressed beyond the elastic limit in tension on the outside and in compression on the inside of the bend. There is only one line, the natural line which retains its original length. The neutral axis lies at a distance of 30 to 50% of thickness of the sheet from the inside of the bend. Stretching of the sheet metal on the outside makes the stock thinner. Bending is sometimes called as forming which involves angle bending, roll bending, and roll forming and seaming and spinning. Well designed fixtures are also used where mass bending of such components is required. Bending occurs when forces are applied to localized areas, such as in bending a piece of metal into a right angle, and forming occurs when complete items or parts are shaped. However, some common kinds of sheet metal bends using by press brake

dies are depicted in Fig. Source A Textbook of Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.