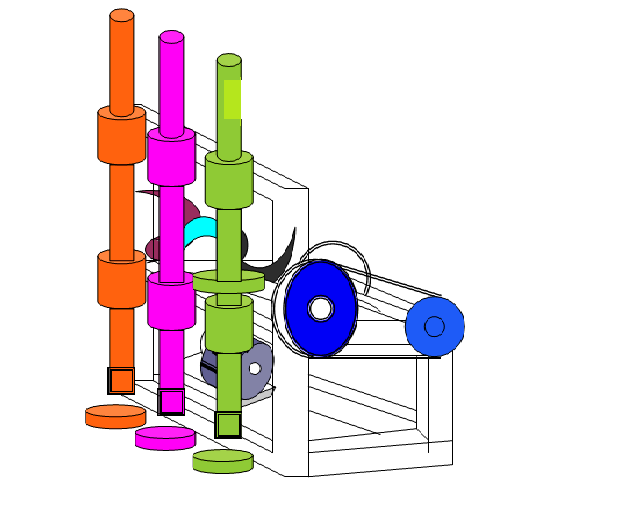

Cam Operated Hammer, Bending machine-Mechanical Project

SYNOPSIS

The project “CAM HAMMER” being compact and Portable, handy equipment, which is skillful and is having some thing different from the ancient conventional hammering process. Most of the material is made available by our college. The sub-components we could easily manufacture in our college work- shop. It’s manufacturing price is also less. This project gives us knowledge,

experience , skill and new ideas of manufacturing. It is a working project and having guarantee of success. This project is the equipment useful to improve the quality of the gear being manufactured and can be made in less time, hence we have selected this project.

Operation:

To operate the cam hammer machine, electric motor, which is having 1440 rpm with the operating voltage of 250V A.C. in single phase with the continuous rating. It’s horse power is 0.5 is used to rotate the cam shaft on which the pair of cam is installed. As the camshaft and cam rotates, it raises the follower plate along with it during its rise period.

The follower plate being installed on the ram shaft raises the ram along with it. As the cam reaches it’s maximum height its down of fall period suddenly starts loosing its contact with the follower plate and the ram is suddenly lowered down with an impact on the table plate. The job along with the required die is kept on the table is exerted with the impact loading deforming it to the desired shape.

The rise of cam and follower and the stiffness of the retaining determines the intensity of the impact exerted on the job. If the speed of the operation of the cam increases the molecules of the material of the job-components finds no time to retain and this will help in obtaining the deformed shape and size due to easily recovery of plastic stage rather the elastic stage. Thus the rpm i.e. the speed of operation of the cam plays an vital role in the forging operation. As the stiffness of the spring is increased the intensity of the impact loading also goes on increasing.

Following Operations can be performed On this Machine

1) Shearing:

In shearing operation as the punch upon the metal, the pressure exerted by the push files cause the plastic deformation of metal. Since the clearance between the push and die is very small, the plastic deformation take place in localized area and the metal adjacent to the cutting edges of the punch and die edges becomes highly stressed, which causes the fracture to start on both sides of the sheet as the deformation progresses. When the ultimate strength at the material is reached as a punch continues to descend the fracture meets at the center of the plate. The metals now completely sheared from the sheet and drops down through and die opening.

2) Blanking:

Blanking is the operation of cutting out flat areas to some desired shape. Blanking is usually the first step in series of operations. The metal punched out is the required production in blanking. For blanking the shear angle is given on the die.

3) Punching:

Punching operations differs from blanking in that, in punching the metal removed per punch usually much less than that removed by blanking. Secondly the shear angle is on the punch and the metal removed is scrap.

4) Piercing:

Piercing is the operation of producing a number of eventually spaced holes in a regular pattern on the sheet metal.

5) Notching:

It is the operation of removal of metal to the desired shape from the edge of the plate. It is similar to punching and piercing.

6) Slitting:

It is the operation of cutting a sheet metal in a straight line long the length.

7) Lancing:

It consists of cutting the sheet of metal through small length and then bending this cut portion. The cutting and lancing operations are shown below:

8) Forming:

It is the operation of bending a sheet of metal along a curved axis, such as U-shapes.

9) Drawing:

It is the operation of bending a sheet of producing cup shaped parts from flat sheet metal blanks by bending and plastic flow of metal.

Its special features are:

- It applies the accuracy up to 1 micron.

- It is light in weight and hence it is portable.

- Weight of machine is 60 kg.(approx.)

- It requires very low maintenance. Also its setting time is less.

- It requires very low floor space area.

- Its manufacturing cost is also very low.

- It requires low power for its operations hence it can be excited using d.c. power and d.c. motor (also to be used in remote areas also).

- It is compact. Total length of machine is 1200 mm.

- Stroke length = 200mm(max)

- Impact = 500kg(max)

- Approximate weight = 60kg.

- Operating torque required = 373 N-m