COLD ROLLING

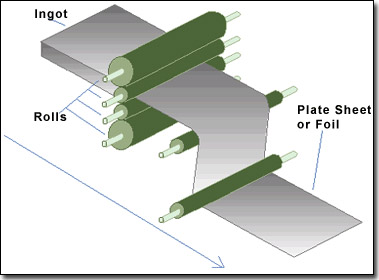

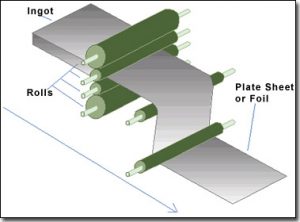

Cold rolling process setup is similar to hot rolling. Bars of all shapes such as rods, sheets and strips are commonly finished by rolling. Foil is made of the softer metals in this way. Coldrolling metals impart smooth bright surface finish and in good physical and mechanical properties to cold rolled parts. If the objective is only to give a clean, smooth finishing metal, only a superficial amount of rolling will be needed. On the other hand, where it is desirable that the tensile strength and stiffness be increased substantially, the section thickness is significantly reduced, and then higher roll pressures and deeper kneading are necessary. Cold rolling also improves machinability in the cold rolled part by conferring the property of brittleness, a condition, which is conducive to smooth tool, finishes with broken chips. The preliminary step to the cold-rolling operation, the sheets of pre hot-rolled steel are immersed in an acid solution to remove the washed in water and then dried. The cleaned steel is passed through set of rolls of cold rolling process thereby producing a slight reduction in each the required thickness is obtained.

The arrangement of rolls in a rolling mill, also called rolling stand, varies depending on the application. The various possible configurations of rolls are similar to hot rolling. The names of the rolling stand arrangements are generally given by the number of rolls employed.

These stands are more expensive compared to the non-reversible type because of the reversible drive needed. Internal stresses are set up in cold rolled parts which remain in the metal unless they are removed by proper heat-treatment. This process needs more power for accomplishing the operation in comparison to hot rolling. Source A Textbook of Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.