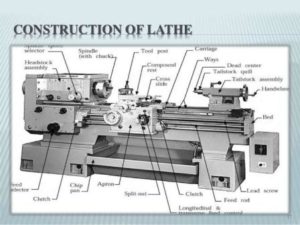

CONSTRUCTION OF LATHE MACHINE

A simple lathe comprises of a bed made of grey cast iron on which head stock, tail stock, carriage and other components of lathe are mounted. Fig. shows the different parts of engine lathe or central lathe. The major parts of lathe machine are given as under:

1. Bed

2. Head stock

3. Tailstock

4. Carriage

5. Feed mechanism

6. Thread cutting mechanism

1. Bed

The bed of a lathe machine is the base on which all other parts of lathe are mounted. It is massive and rigid single piece casting made to support other active parts of lathe. On

left end of the bed, head stock of lathe machine is located while on right side tail stock is located. The carriage of the machine rests over the bed and slides on it. On the top of the bed there are two sets of guide ways-inner ways and outer ways. The inner ways provide sliding surfaces for the tail stock and the outer ways for the carriage. The guide ways of the lathe bed may be flat and inverted V shape. Generally cast iron alloyed with nickel and chromium material is used for manufacturing of the lathe bed.

2. Head Stock

The main function of head stock is to transmit power to the different parts of a lathe. It comprises of the head stock casting to accommodate all the parts within it including gear train arrangement. The main spindle is adjusted in it, which possesses live centre to which the work can be attached. It supports the work and revolves with the work, fitted into the main spindle of the head stock. The cone pulley is also attached with this arrangement, which is used to get various spindle speed through electric motor. The back gear arrangement is used for obtaining a wide range of slower speeds. Some gears called change wheels are used to produce different velocity ratio required for thread cutting.

3. Tail Stock

Fig. shows the tail stock of central lathe, which is commonly used for the objective of primarily giving an outer bearing and support the circular job being turned on centers. Tail stock can be easily set or adjusted for alignment or non-alignment with respect to the spindle centre and carries a centre called dead centre for supporting one end of the work. Both live and dead centers have 60° conical points to fit centre holes in the circular job, the other end tapering to allow for good fitting into the spindles. The dead centre can be mounted in ball bearing so that it rotates with the job avoiding friction of the job with dead centre as it important to hold heavy jobs.

4. Carriage

Carriage is mounted on the outer guide ways of lathe bed and it can move in a direction parallel to the spindle axis. It comprises of important parts such as apron, cross-slide, saddle, compound rest, and tool post. The lower part of the carriage is termed the apron in which there are gears to constitute apron mechanism for adjusting the direction of the feed using clutch mechanism and the split half nut for automatic feed. The cross-slide is basically mounted on the carriage, which generally travels at right angles to the spindle axis. On the cross-slide, a saddle is mounted in which the compound rest is adjusted which can rotate and fix to any desired angle. The compound rest slide is actuated by a screw, which rotates in a nut fixed to the saddle.

The tool post is an important part of carriage, which fits in a tee-slot in the compound rest and holds the tool holder in place by the tool post screw. Fig. shows the tool post of centre lathe.

5. Feed Mechanism

Feed mechanism is the combination of different units through which motion of headstock spindle is transmitted to the carriage of lathe machine. Following units play role in feed mechanism of a lathe machine-

1. End of bed gearing

2. Feed gear box

3. Lead screw and feed rod

4. Apron mechanism

The gearing at the end of bed transmits the rotary motion of head stock spindle to the feed gear box. Through the feed gear box the motion is further transmitted either to the feed shaft or lead screw, depending on whether the lathe machine is being used for plain turning or screw cutting.

The feed gear box contains a number of different sizes of gears. The feed gear box provides a means to alter the rate of feed, and the ration between revolutions of the headstock spindle and the movement of carriage for thread cutting by changing the speed of rotation of the feed rod or lead screw.

The apron is fitted to the saddle. It contains gears and clutches to transmit motion from the feed rod to the carriage, and the half nut which engages with the lead screw during cutting threads.

6. Thread Cutting Mechanism

The half nut or split nut is used for thread cutting in a lathe. It engages or disengages the carriage with the lead screw so that the rotation of the lead screw is used to traverse the tool along the work piece to cut screw threads. The direction in which the carriage moves depends upon the position of the feed reverse lever on the head stock.

Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Singh.