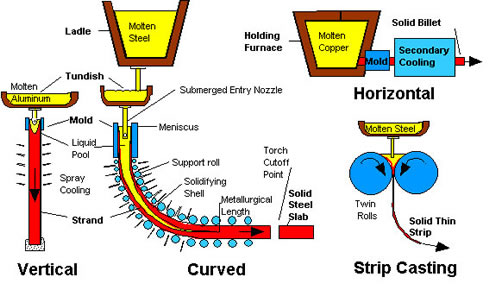

CONTINNOUS CASTING

In this process the molten metal is continuously poured in to a mold cavity around which a facility for quick cooling the molten metal to the point of solidification. The solidified metal is then continuously extracted from the mold at predetermined rate. This process is classified into two categories namely Asarco and Reciprocating. In reciprocating process, molten metal is poured into a holding furnace. At the bottom of this furnace, there is a valve by which the quantity of flow can be changed. The molten metal is poured into the mold at a uniform speed. The water cooled mold is reciprocated up and down. The solidified portion of the casting is withdrawn by the rolls at a constant speed. The movement of the rolls and the reciprocating motion of the rolls are fully mechanized and properly controlled by means of cams and follower arrangements.

Advantages of Continuous Casting

(i) The process is cheaper than rolling

(ii) 100% casting yield.

(iii) The process can be easily mechanized and thus unit labor cost is less.

(iv) Casting surfaces are better.

(v) Grain size and structure of the casting can be easily controlled.

Applications of Continuous Casting

(i) It is used for casting materials such as brass, bronzes, zinc, copper, aluminium and its alloys, magnesium, carbon and alloys etc.

(ii) Production of blooms, billets, slabs, sheets, copper bar etc.

(iii) It can produce any shape of uniform cross-section such as round, rectangular, square, hexagonal, fluted or gear toothed etc. Copied from A Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.