CUTTING SPEED AND FEED

CUTTING SPEED

Cutting speed for lathe work may be defined as the rate in meters per minute at which the surface of the job moves past the cutting tool. Machining at a correct cutting speed is highly important for good tool life and efficient cutting. Too slow cutting speeds reduce productivity and increase manufacturing costs whereas too high cutting speeds result in overheating of the tool and premature failure of the cutting edge of the tool. The following factors affect the cutting speed:

(i) Kind of material being cut,

(ii) Cutting tool material,

(iii) Shape of cutting tool,

(iv) Rigidity of machine tool and the job piece and

(v) Type of cutting fluid being used.

Calculation of cutting speed Cs, in meters per minute

Cs = ((22/7) × D × N)) /1000

Where,

D is diameter of job in mm

N is in RPM

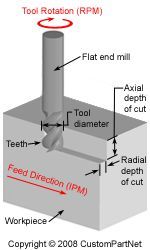

FEED

Feed is defined as the distance that a tool advances into the work during one revolution of the head stock spindle. It is usually given as a linear movement per revolution of the spindle or job. During turning a job on the center lathe, the saddle and the tool post move along the bed of the lathe for a particular feed for cutting along the length of the rotating job.

Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Singh.