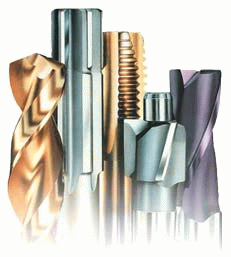

CUTTING TOOL MATERIAL

Few material for cutting tools are generally used which are as follows.

(i) High Speed Steel

These have superior hot hardness and it can retain the hardness up to 900°C. In it tungsten produces martensite structure with other elements. It is three types 18-4-1 High Speed Steel.

It has 18% tungsten, 4% chromium, 1% vanadium and 0.7% carbon: This is used for machining or metal cutting speed above 50 m/min. But for higher cutting speed vanadium is increased.

Molybdenum high Speed Steel

It has 6% Molybdenum, 4% chromium and 2% vanadium.

Cobalt High Speed Steel

It is also known as super high speed steel. It has 1-12% cobalt, 20% tungsten, 4% chromium and 2% vanadium. It is very good for high cutting speed.

(ii) Cemented Carbides

The use of tungsten as an alloying elements gives steel the properly of retaining hardness at high temperature up to 900°C to 1000°C. Carbide is made by mixing tungsten metal powder with carbon and heating the mixture to the about 1600°C in the atmosphere of hydrogen until the two substance have under gone the chemical reaction to produce tungsten carbides. Cemented carbide is a powder metallurgical product. The powder of several carbide compounds are pressed and bonded together in a matrix to from a cemented material. Today, the following three groups of cemented carbides are extensively applied for cutting elements of tools.

(a) WC + Co + (WC-TiC-TaC-NiC) for use in the machining of steels.

(b) WC + Co for use in the machining of cast irons and non ferrous metals.

(c) TiC + Ni + Mo for use in the machining of high temperature high strength metals.

Cemented carbides have a very high hardness (second only to diamond) and high wear resistance to abrasion. They do not loose their cutting properties i.e., hardness over a wide range of temperature up to 900-1000°C. Therefore tools tipped with cemented carbides are capable of efficiently machining the hardest metals, including hardened steels at high cutting speeds. Such tools can operate at cutting speeds from 16 to 25 folds those permitted for tools made of carbon tool steels. One drawback of cemented carbides is their brittleness. Very high stiffness (Young’s modulus is about three times that of steel) of the cemented carbides requires that they are well supported on a shank of sufficient thickness, for even a small amount of bonding deformation in a material of this stiffness may induce very high tensile stresses. Cemented carbides are weak in tension than in compression. They have a strong tendency to form pressure welds at low cutting speeds. In view of this they should be operated at speeds considerably in excess of those used with high speed steel tools. This caused for machine tools of increased power. Carbides that obtain high cobalt percentage are tougher and stronger than that contain low cobalt. Hence they are used for rough cutting, interrupted cuts and for milling. The low cobalt variety is used for finished operations such as turning with a smooth chip cross-section and a continuous cut. It is recommended to keep the braze metal as thin as possible.

(iii) Ceramics Tool

The latest development in the metal cutting tools uses Aluminium oxide, generally referred as ceramics. These tools are made by compacting Al2O3 powder in a mould at about 280 kg/cm2 or more. The part is then sintered at 2200°C. This method is also known cold pressing ceramic tool. Hot pressed ceramic tool materials are expensive owing to their higher mould costs. These are made in form of tips that are clamped to metal shanks. These tools have very low heat conductivity and possess extremely high compressive strength. However they are quite brittle. The have low bending strength. They can with stand temperatures up to 1200°C and can be used at cutting speeds 10 times that of high speed cutting tools and 4 times that of cemented carbides. They are chiefly used for single point cutting tools for semifinish and turning of cast iron, plastics and other work. Heat conductivity of ceramics is very low and hence these tools are generally used without a coolant.

(iv) Carbides tool

It may be produced from carbides of tungsten, titanium and tantanum with same percentage, of cobalt. The product is obtained by a special technique known as powder metallurgy. Usually it contains 82% tungsten, 8% cobalt and l0% titanium and the product is obtained by a special technique known as power metallurgy.

Cobalt acts as a binder and others are very hard substance. This tool contains high degree of hardness and resistance. It is able to retain hardness at elevated temperatures up to l000°C. It can be operated at speeds 5 to 6 times or (more) higher than those with high speed steel.

(v) Diamond

It is a noble material which is so costly that its application becomes limited. It is a hardest material. It can be used for cutting at a speed 50 times greater than H.S.S. tools. It can retain its hardness even at a temperature of 1650. It has low coefficient of friction and high heat conductivity. Diamond tools are used to produce good surface finish.

Reference Introduction to basic Manufacturing Processes and Workshop Technology by Rajender Singh.

For engineering project visit this page regularly for know more things related project ideas. Click here to see Ideas of Projects. Engineers Gallery. All the Best!

Post Comment

You must be logged in to post a comment.