Cutting Tools Used In Carpentary Shop

Various kinds of cutting tools namely various kinds of saws, planes, chisels, scraper, files, and rasp adze and axe and boring tools such as brace and bits, bradawl, auger, gimlet are used in the carpentry shop. Few important types of cutting tools are described as under.

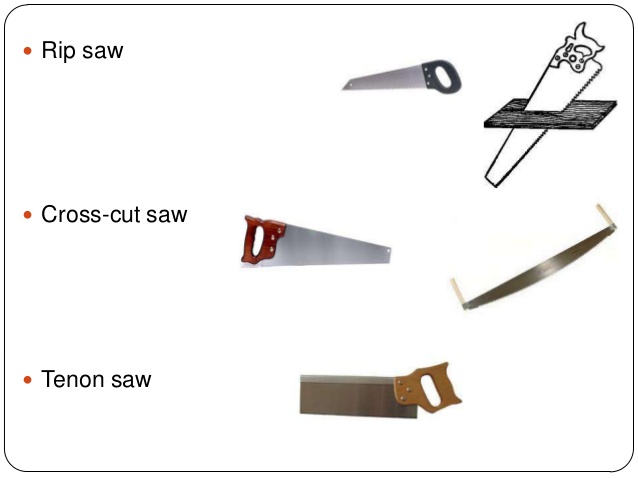

1. Saws

Saws are wood cutting tools having handle and a thin steel blade with small sharp teeth along the edge. They are utilized to cut wood to different sizes and shapes used for making the wooden joints that hold parts together. They can be further classified into three major types namely hand Saws (Rip, Cross-cut, Panel, Keyhole and, Pad saw), Snuff Saws (Tenon and Dovetail) and Frame Saws (Coping, Bow and Fret). Few important types of saws are described as under.

Rip Saw

It is used for cutting timber along the grains. The teeth of rip saw are chisel-shaped and are set alternately to the right and left. A 24″ long point saw is a good for sawing work. Depending upon whether the saw is designed to rip or cross-cut, the shape of the teeth will also vary. In the case of a ripsaw, the teeth are shaped like chisels.

Crosscut Saw

Cross cut saw is similar to rip saw in shape. It is primarily designed for cutting across the grains of wood. The teeth are knife shaped and bent alternately to the right and left for making the saw to cut wider than the blade. The saw cut is called the kerf. Since the kerf is wider than the blade, the blade will not stick as the sawing is done. The saw teeth may be coarse (with only 4 or 5 teeth per inch) or fine (with ten or twelve teeth per inch). A jaw for general purpose cutting should have about eight or nine points per inch (there is one more point than teeth per inch) and should be about 24 inches long.

Turning Saw

The turning saw is similar to the copying saw which is designed for cutting curves, scrolls and roundings on wooden jobs. It is used chiefly on heavier work where long fast stroke and less accuracy of cutting are required. The thin blade of the turning saw is removable. This saw can be pivoted between the handles. The saw generally cuts in the pulling stroke.

Dovetail Saw

Dovetail saw is little and is closely similar as related to the backsaw or tennon saw. It is lighter and however possesses a thinner blade and finer teeth.

The handle is round, to provide a delicate grip for fine cutting. This saw is used where absolutely finer and delicate cutting is required in wood work.

Compass Saw

Compass saw carries a tapered blade which is one of the special saw having thin, narrow and flexible blade. With a blade resembling the beak of a swordfish, this type of saw is commonly used for making cutouts on the inside surface of a piece of work. A hole is first bored inside the portion which is to be cut out and the pointed compass saw is pushed into the hole to start the sawing operation. Its blade contains about 12 teeth per cm length.

Keyhole Saw

The keyhole saw is used in the same manner as the compass saw. For this reason it is generally employed for fine internal and intricate work where the compass saw would be too big and clumsy for the carpentry job.

Hacksaw

Hacksaw consists of steel frame and a hacksaw blade. While essentially designed for cutting metal, this tool comes in for a variety of uses in the wood working shop. The frame of hacksaw is designed in different ways, some with pistol grips, others with handles similar to those used on a conventional saw and others with turned handles. Blades of hacksaw are detachable and can be obtained with teeth of varying coarseness.

2. Planes

A plane is a special tool with a cutting blade for smoothing and removing wood as shavings. It is just like a chisel fixed in a wooden or steel body. The modern plane has been developed from the chisel. They can also be classified as jack plane, smooth plane, jointer plane, trying plane, rabbit plane, circular plane and fore plane. Few important planes are discussed as under.

Jack Plane

Jack plane is most commonly used plane which is comprises

of its body about 40 cm long, blade 5-6 cm wide and handle. It is good for rough surfaces that require a heavier chip. It is ideal for obtaining a smooth and flat surface. There are actually forty-six different parts of jack plane, the carpenter needs only acquainted with the working or regulating parts. The main working parts are the cutting blade or plane iron. The adjusting nut is operated to raise or lower the blade and the adjusting lever which regulates the blade so as to make possible an even or slanted cut. The cutting blade of the jack plane is guarded with a metal cap which is adjusted on top of the blade to within about 2.4 mm of the cutting edge. The metal cap of the jack plane eases the cutting action by curling and breaking off the wood shavings evenly, thus preventing splitting or splintering of the wooden part.

Smoothing Plane

Smoothing plane is somewhat smaller than the jack plane, measuring between 6 and 10 inches in length. It is a fine utility tool, especially useful for planning end grain, chamfering, and other edge shaping of wooden part. This plane is also used for cleaning up after gluing and assembly, but owing to its short length should not be used for producing very true surfaces.

Jointer Plane

When a fairly long board is to be planed absolutely straight and square along the edge, it is easier to obtain a straight and level surface with the jointer plane in comparison to any other type of plane. This plane is made up in various sizes but the most popular type of jointer plane is 24 inches in teeth.

Trying Plane

The wooden trying plane is similar in construction to the jack plane except that its blade is wider and much longer than jack plane. Its mouth is also narrower than that of the jack plane.

Rabbet Plane

Rabbet plane is used for sinking one surface below another and shouldering one piece into another. If the edge of a piece of wooden board is to be rabbeted, this plane is being generally used.

The side guide and the cutting blade of the rabbit plane may be adjusted so as to cut rabbets of varying widths and depths. The plane is useful for various types of edge shaping. Rebate or rabbet means a recess or step cut into the edge or end of a wooden board.

Circular Plane

The shape of circular plane adapts it for planning either convex or concave surfaces and for shaping round edges. This plane may be adjusted so that the flexible bed will conform to circles of various sizes.

Fore Plane

This plane may be said as a junior jointer plane. It is slightly shorter than the conventional jointer plane. It is mainly used for planning edges of medium length.

3. Chisels

A Chisel is a strong sharp edge cutting tool with a sharp bevel edge at one end. Its construction is composed of handle, tang, ferrule, shoulder, and blade. Chisels are generally made up of high carbon steel. They are used to shape and fit parts as required in joint making.

A gouge is a curved chisel. It may be outside or inside ground. Outside ground gouges are called firmer gouges and inside ground gouges are called scribing gouges. The scribing gouges are made long and thin, they are known as paring gouges. Several varieties of chisels are available, each having special characteristics which fit it for its special use. There are two types of construction employed in the making of chisels named as tang and socket types. The tang chisel is made with a ranged or pointed end which pierces into the handle. The socket chisel reverses the process by having the handle fit into the socket collar on the blade.

Firmer Chisel

Firmer chisel is possesses a blade of rectangular section. It consists of the following parts blade made of cast tool steel and it is used for general bench work. The shoulder of the chisel prevents the tang from being driven farther into the handle when the chisel is struck with a mallet. The ferrule is short length of brass tube (mild steel tube in the case of some mortise chisels) which fits tightly over the lower end of the handle, and helps to prevent its splitting by the tang. The tang is not hardened as to fit in the handle. The handles turned from ash or beech wood as these timbers are resistant to splitting. Beveled edge firmer chisel

Beveled edge firmer chisel is identical to the firmer chisel except that the edges of the back of the blade are beveled. This enables the chisel to be used for cutting right into the corner of acute-angled wood work such as the base of a dovetail.

Paring Chisel

Paring chisel has a longer and usually slightly thinner blade than firmer chisel. It may be obtained with a blade of rectangular or beveled edge section and is used in pattern making and where long accurate paring is required. The paring chisel should not be struck with a mallet. This chisel is intended for manipulation by hand only, and not for driving with a mallet like a firmer chisel for cutting of wooden jobs.

Mortise Chisel

Mortise chisel is designed for heavy work. A mortise chisel has a blade which is very nearly square in section and so may be used as a lever for removing chips and will withstand heavy blows from a mallet. Various types of handles are fitted to mortise chisel depending upon use. Mortise chisel has an oval beech handle, whilst the heaviest type of all has a socket handle. This socket replaces the ferrule and affords greater resistance to splitting when used for very heavy work. The leather washer acts as a shock absorber.

4. Scraper

The scraper for wooden work is used in carpentry shop. It is used after planning to obtain a smooth surface before final glass papering. Where the grain in wood is particularly twisty

so that even a finely set plane tends to tear it, a sharp scraper will be found most useful to tackle this problem. It is also used for cleaning up veneered work as its curved edges are used for cleaning up large molding of concave section and other similar work. The scraper is held as the thumbs being positioned low down and pushed forward to curve the blade so that the center of the edge rather than the outer corners comes into contact with the surface of the wood. A sharp scraper will produce fine shavings on wooden surfaces.

5. Files and Rasps

They are of used for maintaining other wood working tools and equipment. They are made of hardened tool steel which is tempered and they should never be dropped as they are very brittle to break. They are of various types depending upon their size, shape, cuts and degree of their coarseness.

6. Adze

An adze is used for rough cutting, squaring, to chop inside curves and to produce concave surfaces. Its outer face is convex, inner face concave and edge is beveled to form a cutting edge. It is made of carbon steel.

7. Axe

An axe is used for splitting the logs and for removing bark from the wood. It is made of carbon steel and both sides are beveled to form a cutting edge. Its one side is plane and the other is beveled to form a cutting edge. It is used to make the surface roughly plane.

8. Boring Tools

Boring is cutting a hole in wood with a tool called a bit. Holes of 6 mm size or larger are bored. Holes of 6 mm size or smaller are drilled. Boring is the first step in making any kind of shaped opening or making holes. The commonly used boring tools bits are discussed as under.

The center bit

The center bits are available in sizes ranging .from 4 mm to 50 mm and are useful for boring holes through thin wood. They are not recommended for deep boring as it has a tendency to wander or drift as a result of varying grain texture and direction in wood.

The screwed center of the improved center bit helps to draw the bit into the wood and therefore requires less pressure to obtain a cutting action.

Auger bits

The auger bits are also known as twist bit. They are the most commonly used hole making tools used in wooden wood. They may possess a single twist auger bit or a double-twist auger bit. These bits are more costly than center bits. They can produce holes easily and accurately from 5mm to 35 mm in diameter in wooden jobs. The hollow features are important in both types of auger bits, because the parallel sides of the bit help to prevent drifting. And the twisted form of the body of the bit helps in the removal of cuttings. Both these bits have two cutters and two spurs as well as a screw center for quick and clean boring action in wood work.

Countersink bits

Countersink bit is used for countersinking the predrilled holes to placement of heads of screws.

Shell and spoon bit

Shell and spoon bits are the traditional kinds of bit which are now superseded by the carpenter’s twist drills or bits.

Expanding bits

These are commonly used forms of screw center bit which are adjustable for cutting holes of from 15 mm to 75 mm in diameter. The two combined cutter-spurs are provided in each case to cover the range of hole sizes.

Forstner bits

These are used for boring clean sided stopped holes of flat bottom kind.

Snail bits

The snail bits have only one cutter which gives a clean cutting action.

Rose bits

The rose bit tends to scrape rather than cut. It is generally used on soft metals in addition to wood.

Bradawl

Bradawl is used for making fine holes, especially nail holes in soft woods. The cutting edge of the blade, which is sharpened equally from both sides, is placed across the grain so that the wood fibers are severed and not merely forced outwards. The blade is forced into the wood and it is then allowed to twist for enlargement of the diameter of the hole being bored and then finally removed. The cutting edge of the blade of bradawl is flared out to give clearance to the body of the blade which is fixed to the handle by means of a square-tapered tang. A brass ferrule is fitted to prevent the tapered tang splitting the handle when being pushed into it. The blade of bradawl is shouldered to prevent its being forced further into the pear-shaped handle which is usually turned from ash, box or wood.

Auger

The auger is a carpentry hand tool (made up of steel bar) and is used to make holes in the wooden jobs. It possesses a screw point to center the tool at the point where hole is to be produced in the wooden part. Fluted body of the auger is to allow removal of wooden chips from wooden jobs using handle to apply pressure to rotate the auger for making the hole. Holes up to 25 mm diameter can be produced. Copied from Basic of Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.