Introduction

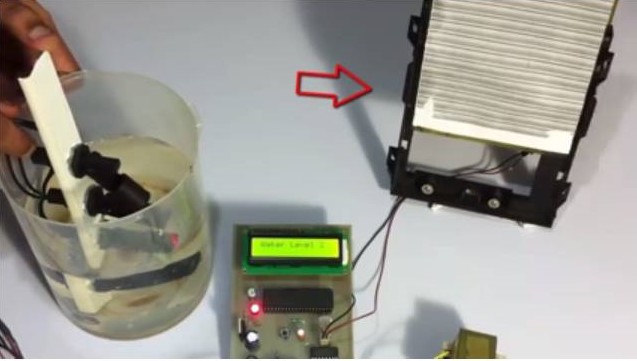

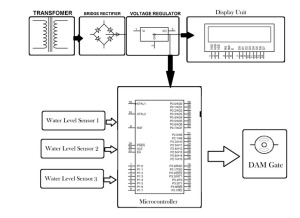

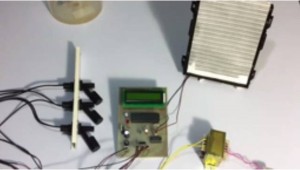

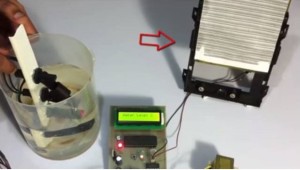

We here propose an automatic dam water level monitor and controller system. Our proposed project uses sensors to sense the water level and then opens the dam gate (motor used to demonstrate as dam gate) according to the water level. Our system uses multiple water level sensors (float sensors) for this purposes. The sensors are mounted at three different levels in order to check water level and provide signals accordingly. When water reaches first sensor it is sensed by it and displayed. When water reaches second sensor it provides a signal to the micro-controller and it opens the dam gate partially. As soon as the water level reaches the third sensor, it signals the micro-controller and the micro-controller then signals the motor to run, which is demonstrated as opening the dam gate fully. Thus our proposed system allows for automatic dam gate opening based on water level sensing.

Hardware Specifications

- 8051 Family Micro-controller

- DC Motor

- Capacitors

- Motor Driver

- LCD Screen

- Water Level Sensors

Software Specifications

- Keil µVision IDE

- MC Programming Language: Embedded C

Water Level Sensors

The UCL-510 offers an innovative, non-contact ultrasonic level sensor with no moving parts built for challenging fluid measurement. This accurate and reliable sensor is built for general purpose, small tank applications 49.2″ (1250 mm) or less and offers switch, controller and transmitter capabilities in one multi-function transmitter. The UCL-510 is suited for corrosive and dirty applications and is virtually maintenance free and reduces tank system hardware. The UCL-510 combines 4 relays, 4-20mA output and pump/valve control in one small sensor. The UCL-510 offers a total solution for fluid handling and automation.

Applications:

- Water and Waste Water

- Control Automation

- Chemical Feed

- Food and Beverage

- Acids, Inks, Paints

- Slurries

Post Comment

You must be logged in to post a comment.