DESIGN AND ANALYSIS OF DIFFERENTIAL GEARBOX- FULL REPORT DOWNLOAD

Abstract

Abstract My Project “DESIGN AND ANALYSIS OF DIFFERENTIAL GEARBOX” mainly focuses on the mechanical design and analysis of gearbox as transmit the power. I had developed this work as my semester project with a view to get familiar with the technologies as well as application of theories into practical work done by industries. My project contains the design and material selection of the gearbox for different type of vehicles also. For better efficiency, improvement of power transmit rate is important phenomenon.

Introduction

Gearboxes are used in almost every industry right from power to marine, and also include agriculture, textile, automobiles, aerospace, shipping etc. There are different types of gearboxes available for varying uses. These gearboxes are constructed from a variety of materials depending on their end use and the kind of industry they are being used in. The product has numerous industrial applications for providing high torque and smooth speed reductions. These gearboxes are also manufactured keeping certain specifications in mind, which will also vary depending on the application.

Functions of a Gearbox

1. A gearbox is precisely bored to control gear and shaft alignment.

2. It is used as a housing/container for gear oil.

3. It is a metal casing for protecting gears and lubricant from water, dust and other contaminants.

Simple differential Gear box:

Bevel gearboxes are special speed reducers with their shafts lying perpendicular to each other and therefore used mainly in right-angle applications. The gearbox is a kind of right angle gear and is suitable for a right angle solution with a low ratio. These gearboxes save more energy as compared to worm gears and are available in varying gear ratios.

Materials Used

- These gearboxes are constructed from a variety of materials. Some of the popularly used materials are

- The ratio of a bevel gearbox can be determined by dividing the number of teeth in the larger gear by the number of teeth in the smaller one. These gearboxes generate varying level of torque and can also be customized to suit individual requirements.

Differential Gear box Design include Following steps:

- Design of bevel gears according to speed and power transmission in kw.

- Design of bearings

- Design of shafts

- Design of keys .

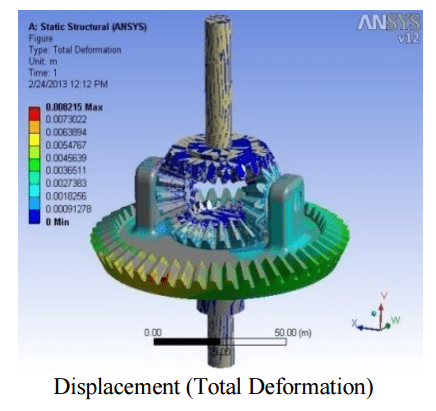

Analysis of Differential Gear box is given in report .