Design and Fabrication Of Arecanut tree Climber -Mechanical Project

Introduction

Arecanut is an erect, unbranched palm reaching heights of 12-30 m, depending upon the environmental conditions. The stem is marked with scars of fallen leaves in a regular annulated form. Arecanut almost always exist in cultivation; therefore, conditions of its natural habitat are difficult to assess. It however thrives in areas of high rainfall. Being a shade loving species, arecanut always does well when grown as a mixed crop with fruit trees. Raising a banana shade crop is even better as this supplements farmer’s income. The majority of arecanut are harvested by climbing the tree and cutting the nuts down by hand. This process may seem simple; however, it is actually quite dangerous. In response, there is a genuine need to develop a device.

Objectives of the project

In an attempt to assist the climbers, an arecanut tree climbing device has been designed to meets

the following goals

- It will be controlled from the ground.

- Both men and women will be able to operate the device.

- The arecanut tree climber will be able to harvest faster than present methods.

Mechanization of conventional methods used in harvesting the crops is very much essential to assist the farmer. The aim is to build a prototype that can successfully climb an arecanut tree of

variable diameters and height.

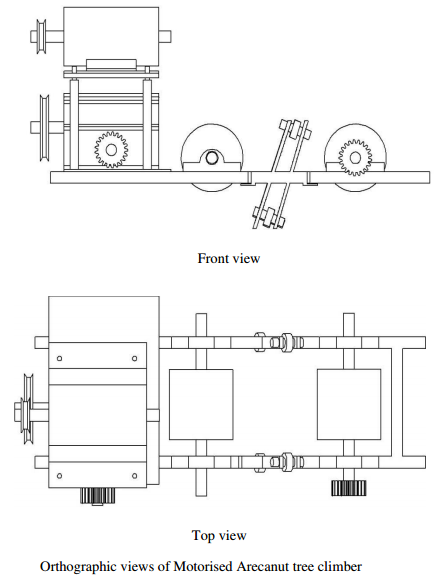

Here we are designing and fabricating motorized arecanut tree climber. The tree climber has a base on which the rollers are fitted using self aligning bearings at a distance as the diameter of a standard areca tree. On one extreme end of the base, gear box and above that the motor is mounted. The power from the motor to the rollers is transmitted by using sprocket and chain drive. To obtain the required speed of the rollers a reduction gear box is used in between the motor and the rollers. The machine is placed around the tree and clamped to it using a swivel opening on one side of the base. Due to the weight of the motor, gear box and some extra mass concentrated on one end of the base the machine locks itself to the tree. Now the motor is switched ON to drive the rollers. When the rollers rotate gripping the tree, the whole setup is lifted along the length of the tree. After reaching the required height the motor is switched OFF. By having suitable auxiliary equipment for spraying pesticides, plucking the nuts on the setup and suitable controlling methods for those equipment the required job can be performed. Once the job is done the motor is made to rotate in the reverse direction to descend down the tree.

The main parts of the Motorized arecanut tree climber are:

- Base

- Roller

- Bearing

- Sprocket and chain

- Pulley and V-belt

- Motor

- Gear Box

The base and rollers are manufactured using mild steel. Mild steel is the most common form of steel because its price is relatively low while it provides material properties that are acceptable for many applications. Low carbon steel contains approximately 0.05–0.15% carbon and mild steel contains 0.16–0.29% carbon, therefore it is neither brittle nor ductile. Mild steel has a relatively low tensile strength, but it is cheap and malleable; surface hardness can be increased through carbonizing. It is often used when large quantities of steel are needed, for example as structural steel. The density of mild steel is approximately 7.85 g/cm3 and the Young’s modulus is 210,000 MPa (30,000,000 psi).Low carbon steels suffer from yield-point run out where the material has two yield points. The first yield point (or upper yield point) is higher than the second and the yield drops dramatically after the upper yield point. If a low carbon steel is only stressed to some point between the upper and lower yield point then the surface may develop Luder bands.

Advantages

- It can be controlled from the ground.

- Both men and women will be able to operate the device.

- The arecanut climber will be able to harvest as fast or faster than present methods.

- It eliminates the risk involved in manual climbing of the areca tree.

Disadvantages

- The lack of vision as the device climbs upwards.

- The development of a multi-axis robotic arm for harvesting is the major design challenge.

- Difficult to have electric supply within the farm.

Post Comment

You must be logged in to post a comment.