Design and fabrication of coconut dehusking machine

Introduction

The scope of this project was to design and develop a coconut fiber extraction machine for farmers and small scale coir industries in India to provide an effective solution to the difficulties in existing process, reduce time and labour cost and to develop a compact coconut fiber extraction machine which could be used in remote villages so that unutilized husks from such areas could be tapped and fiber could be made available to the Coir Industry directly. This project was taken up to develop a promotional strategy for a new innovation and generate public awareness regarding the availability of a coconut fiber extraction machine in the market at a reasonable cost.

The project began with collection of information and data on user lifestyle and current process by which they perform their job. The current difficulties were analyzed. Interviews were held with users. A comparative bench marking study was done on similar processes used in other similar extraction processes. Along with this an ergonomic simulation was made to understand the user difficulties and manufacturing methods to get an overview to provide solution to the user to suit their requirement.

Concepts were generated keeping benchmarked product in view. Five concepts were generated with different functions and operating processes for coconut fiber extraction machine. Final concept was selected by considering the users’ operating environment and maintenance, which could be used in small scale coir industries and in the farm sector. Considering the users’ needs and buying capacity, a prototype was fabricated. This machine works with gear mechanism, in which 2 barrels rotates in opposite direction to extract fiber from coconut. Cutting pins are inserted in indexed holes to separate fiber and to give linear motion to coconut shell.

Main parts

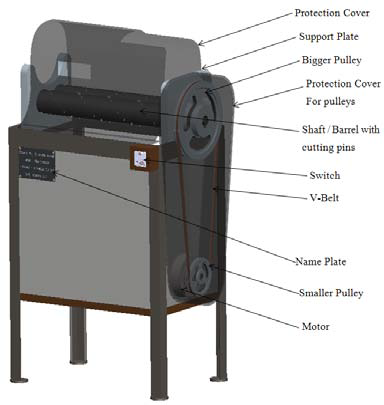

The de-husking unit consists of the following major parts

• Main Frame Left

• Main Frame Right

• Top roller

• Bottom roller

• Blades

• Drive shaft

• Bearings for the rollers

• Moving pressure roller unit

• Scrapper unit

• Flywheel

Detailed Specification of Coconut Dehusking machine

1 Mechanism -Gears and Pulley with belt drive

2 Target Customer-Farmers or small scale Coir industry

3 De-Fiber Process -Motor operated

4 De-Fiber Function – Automatic

5 Material -M.S. for Shaft, Stainless Steel for Cutting tips, Steel for Fabricated body

6 Manufacturing-Machining, Indexing, Bending and Fabrication

7 Safety -Avoid sharp corners, Safety guards

8 Cost -Approx. 12000/- INR

9 Life of the product 2-3 years

10 Motor Specification -¼ HP Single phase AC motor, heavy duty, 1440 RPM

11 Major Pulley diameter -12” (12-B single)

12 Minor Pulley diameter -2” (2-B single)

13 Pulley Ratio -1:6

14 Working RPM -240 RPM

Conclusion

The project comprises of research and user study. Literature study is carried out based on the existing patents on coconut fiber extraction machine, and it is observed that there are difficulties for remote village to supply unutilized husks to coir industries directly. So there is a need to give solution to overcome their difficulties and to arrive at solution, importance is given towards users operating environment and mainly towards constrains like Safety, Function and reliability.

Post Comment

You must be logged in to post a comment.