Design and Fabrication Of Gear and Spline Cutting Attachment In Lathe

Abstract

Mechanical engineering without production and manufacturing is meaningless and inseparable . Also Production and manufacturing process deals with conversation of raw materials inputs to finished products as per required dimensions specifications and efficiently using recent technology.

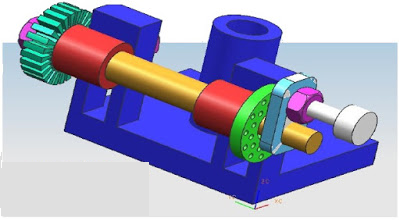

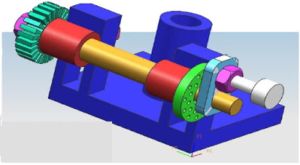

Our project design and fabrication of spline (gear) cutting attachment is used to cut gear or splines over the cylindrical job. Our main aim is prove lathe is a versatile machine thus this gear cutting operation is done using lathe itself.

Working

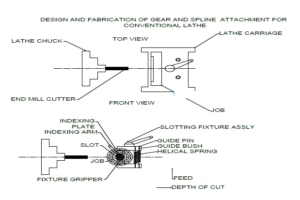

In this project End mill cutter (tool) is fixed in lathe chuck and job is fixed over the compound slide by gear cutting attachment.

this fixture has spindle with indexing plate, here job is hold rigidly in spindle itself Feed is given by cross slide movement. And depth of cut is given by movement of

carriage. When cutter rotate at 1100 Rpm. This is complete using Angular splines. Indexing can be done with the aid of indexing plate.

Advantage

1) Fixture cost is low

2) No need of purchase special machine for this

3) Production cost is low

Disadvantage

1) Accuracy is little bit low

Post Comment

You must be logged in to post a comment.