DESIGN AND FABRICATION OF THE LEAF JIG- MECHANICAL PROJECT

ABSTRACT

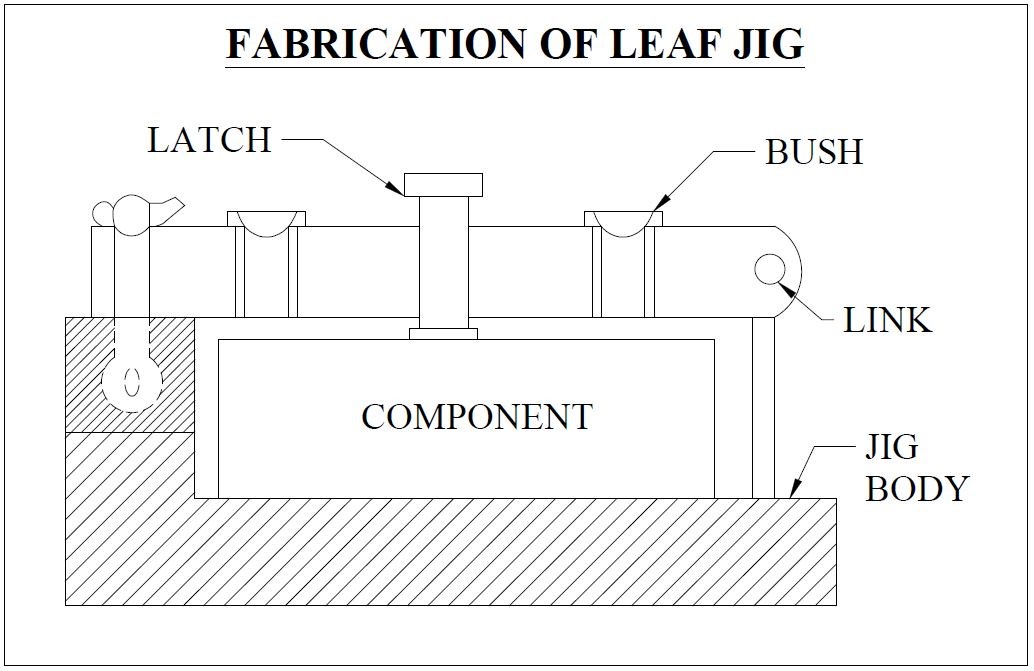

This project is based on the need for the work holding devices. This design and fabrication which will enable the operation like drilling, reaming, tapping process easier even the job profile are Angular. Our project is mainly composed of design and fabrication of the “LEAF JIG” which cover the absolute design to the specified dimensions of the work piece. Angular jig permits drilling holes in one sides of the work piece with a single location and clamping operation this saves time and increase production rate.

INTRODUCTION

Mass production targets on increasing productivity and increasing accuracy by reducing the setup cost and manual fatigue. One of the common practices to achieve the goals of mass production is to use jigs. Let us consider an example that one gets an order of 1000 product in such a way that three holes are to be drilled in a work piece. In such situations, designer will lay out the position of each hole with the help of square, straightness, scribers, centre punch etc. Generally, trial and error method is practiced until the axis of hole is properly aligned with the axis of drill. Thus, a lot of time will be consumed to maintain the accuracy. Ultimately it increases operator’s fatigue. Thus, instead of laying out the position of each hole on each work piece with the aid of square, straightness, scribers, centre punch etc., the operator uses a jig to position and guide the drill into proper place. Drill jig increases productivity by eliminating individual marking, positioning and frequent checking. Interchangeability is one of the advantages of jigs. There is no need for selective assembly. Any of the parts will fit properly in the assembly and all similar components are interchangeable. In addition, a jig reduces the repetitive nature required for drilling a hole, as the locating, clamping and guiding are done by jig itself. The tool-guiding element helps in setting of tool in correct position. Hence, skilled workers are not required. Drill jig makes it possible to drill, ream and tap holes at much faster speed and with great accuracy as compared to holes produced by conventional hand methods. The responsibility for accuracy of hole location is taken from the operator and given to the jig. Jig can be defined as a work piece holding and locating device that positions and guides or controls the cutting tool. Drill jig is device to ensure a hole to be drilled, tapped or reamed in the work piece at proper place. Leaf jig consists of a clamping device to hold the part in the position under hardened steel bushings. Drill passes through the steel bushings during drilling operation. The drill is guided by these bushings. Generally work piece is held by jig and the jig is arranged in such a way that the work piece can be quickly loaded and unloaded.

ADVANTAGES:

• It eliminates the individual marking, positioning and frequent checking.

• The operation time is reduced due to increase in speed, feed and depth of cut because of high clamping rigidity.

• It is very much useful in mass production.

• It makes possible to employ unskilled or semi-skilled operator to make savings in labor cost.

• It partially automates the tools. It reduces the expenditures on quality control of machine parts.

LIMITATIONS:

• It is only used for small size components. It is only used for the elbow pipes with flanges, which has the height of mm.

• Forces causing deflection may come from handling. There is no special way to remove the chips produced by drilling. So it requires separate time.

APPLICATIONS

• Mass production in The following is a partial list of production operations that use fixtures Assembling Lapping Boring Milling Broaching Planning Drilling Sawing Forming Shaping Gauging Stamping Grinding Tapping Heat treating Testing Honing Turning Inspecting Welding

Post Comment

You must be logged in to post a comment.