DEVELOMENT OF PATTERN LAYOUT

Projective geometry forms the basis of successful layout of patterns for making different jobs in sheet metal work. Most of the patterns are obtained from development of surfaces of

some common geometrical solids like cylinder, prism, pyramid and cone. These shapes may be required to be developed either in single or in combination. A sheet metal planner should have a thorough idea of the procedures employed in developing the surfaces of the above solids and their inter-penetrations.

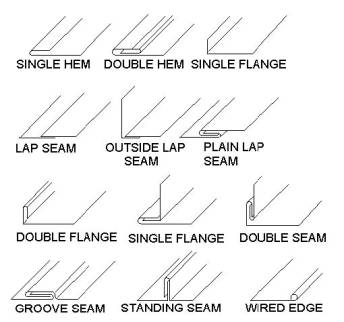

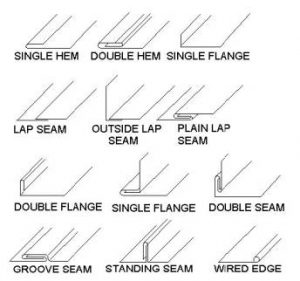

Sheet metal work consists mainly of cutting, forming and assembling the object that has been laid out on flat metal sheet. The outline of the object or pattern is first either scratched on the sheet or drawn on a paper and then transferred to the sheet. Metal sheet is then cut to various shapes and sizes as per the pattern or shape of object, which may be later, transformed to various articles by using different sheet metal processes. In the process of laying out a pattern, certain allowances are kept for making edges and seams. The development of surface is the unfolding or unrolling sheet in one plane. The sheet is used to mark correctly using scriber. Important attention is also invited regarding accounting for the allowance in preparing edges and seams to be made for making joints. The notches of metal pieces are then cut. Finally the edges are then turned to form box as shown through step in Fig.

Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.