EFFECT OF HOT WORKING ON MECHANICAL PROPERTIES OF METALS

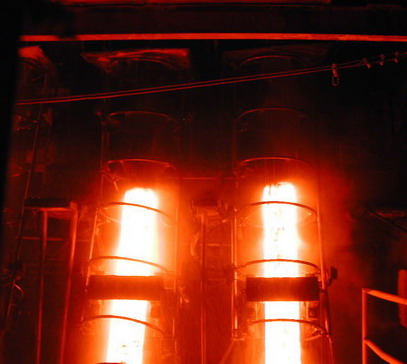

1. This process is generally performed on a metal held at such a temperature that the metal does not work-harden. A few metals e.g., Pb and Sn (since they possess low crystallization temperature) can be hot worked at room temperature.

2. Raising the metal temperature lowers the stresses required to produce deformations and increases the possible amount of deformation before excessive work hardening takes place.

3. Hot working is preferred where large deformations have to be performed that do not have the primary purpose of causing work hardening.

4. Hot working produces the same net results on a metal as cold working and annealing. It does not strain harden the metal.

5. In hot working processes, compositional irregularities are ironed out and nonmetallic impurities are broken up into small, relatively harmless fragments, which are uniformly dispersed throughout the metal instead of being concentrated in large stress-raising metal working masses.

6. Hot working such as rolling process refines grain structure. The coarse columnar dendrites of cast metal are refined to smaller equiaxed grains with corresponding improvement in mechanical properties of the component.

7. Surface finish of hot worked metal is not nearly as good as with cold working, because of oxidation and scaling.

8. One has to be very careful as regards the temperatures at which to start hot work and at which to stop because this affects the properties to be introduced in the hot worked metal.

9. Too high a temperature may cause phase change and overheat the steel whereas too low temperature may result in excessive work hardening.

10. Defects in the metal such as blowholes, internal porosity and cracks get removed or welded up during hot working.

11. During hot working, self-annealing occurs and recrystallization takes place immediately following plastic deformation. This self-annealing action prevents hardening and loss of ductility. Source Introduction of a Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.