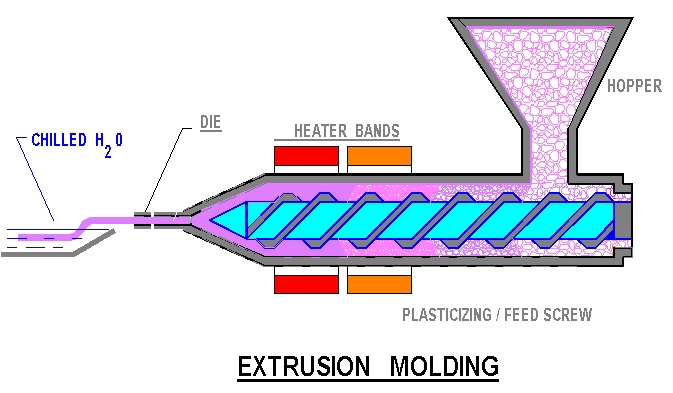

Extrusion Molding

Generally all thermo plastic materials are highly suitable for extrusion in to various shapes such as rods, tubes, sheets, film, pipes and ropes. Thermosetting plastic is not suitable for extrusion molding. In this process the powder polymer or monomer is received through hopper and is fed in to the heated chamber by a rotating screw along a cylindrical chamber.

The rotating screw carries the plastic powder forward and forces it through the heated orifice of the die. As the thermoplastic powder reaches towards the die, it gets heated up and melts. It is then forced through the die opening of desired shape as shown in the sectional view of the extrusion molding process through Fig. On leaving the product from the die, it is cooled by water or compressed air and is finally carried by a conveyor or belt. The process is continuous and involves low initial cost. Copied from A Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

PLASTICS MOLDING PROCESSES

There are various methods of producing components from the plastics materials which are supplied in the granular, powder and other forms. Various plastics molding processes are:

1. Compression Molding.

2. Transfer Molding

3. Injection Molding.

4. Blow Molding.

5. Extrusion Molding

6. Calendaring.

7. Thermoforming.

8. Casting

Post Comment

You must be logged in to post a comment.