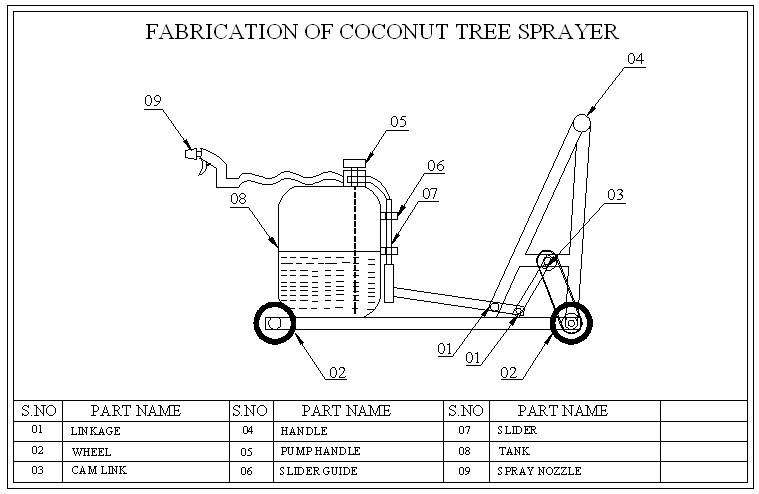

FABRICATION OF COCONUT TREE SPRAYER

Abstract

Nowadays, the growth of coconut tree is highly affected by the harmful insects. These insects attacks on outer layer of the coconut and infects the coconut. To solve this problem, many effective methods are implemented. In this project, we are using the spraying nozzle for spraying the insecticides on the coconuts. A spray nozzle is a spraying equipment that facilitates the formation of spray.

When a liquid is dispersed as a stream of droplets, it is referred as spray. Here, we are using the spray nozzle to achieve two primary functions:

1) It should spread a liquid over an area.

2) It should increase the liquid surface area to increase the evaporation.

The spray nozzle uses the liquid pressure as the energy source to break the liquid into droplets. By using spray nozzle, we can spray and distribute the insecticides, pesticides and water efficiently in the fields. This sprayer consumes less energy than a gas atomized or twin-fluid spray nozzle. As the pressure increases the liquid flow increases and the drop size decreases. But this leads to problems in achieving a certain flow rate at a given pressure and in selecting a specific droplet size. A special nozzle is developed to solve this problem. In certain applications, this nozzle can reduce the need of expensive compressed air. It creates a better and optimum control on the liquid spray. By using this nozzle, we can vary the liquid flow rate at a particular droplet size and pressure. Sprayers range in size from man-portable units. In agriculture field, a sprayer is called as a equipment that applies herbicides, pesticides and fertilizers to the agricultural crops. It is easy to use and works efficiently.

MACHINE COMPONENTS

The fabrication of coconut tree sprayer consists of the following components to full fill the requirements of complete operation of the machine.

1. Hand operated vehicle

2. Pump

3. Link

4. Bearing block

WORKING PRINCIPLE

This project is constructed with the above mentioned parts. In a hand operated vehicle a water tank is fixed on the given area as shown in the figure. Above this tank a pump is placed for the purpose of pumping water from the tank. This pumping operation is done by the linkage with cam arrangement. A rod is connected to the cam arrangement. The other end of the rod is connected to the slider which is connected to the pump lever. This cam arrangement is fixed to the driven sprocket of the chain drive. The driving sprocket is connected to the wheel shaft of the vehicle. This cam is actuated with the help of the chain drive. When the vehicle moves the wheel starts to rotate and the chain drive also functions. By the above process the cam is actuated and this leads to the slider’s reciprocating motion. Due to this operation the pump lever starts to actuate and hence the water is pumped and stays in the outlet tube. When the spray nozzle is pressed the stored water is sprayed out with high pressure. Thus the water or pesticide is sprayed wherever required.

Advantages:

- Very low cost

- No need of power supply

- Easy in construction

- Can be operated easily

Disadvantages:

- The water should be filled manually all the time

Post Comment

You must be logged in to post a comment.