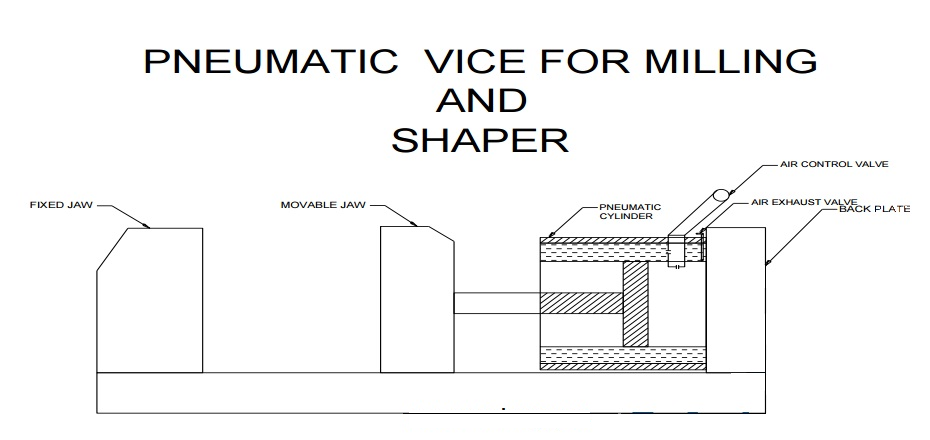

FABRICATION HIGH PRESSURE PNEUMATIC MACHINE VICE

Introduction :

A pneumatic machine can be thought of as a large flexible mechanical structure that is moved by some sort of control system. The control system takes its input from a human operator and translates this command into the motion of actuators, which move the mechanical structure. The high performance and highly powerful, Pneumatic machine vice together with the capacity for high volumes are suited for Holding Heavy Objects.

A pneumatic machine can be thought of as a large flexible mechanical structure that is moved by some sort of control system. The control system takes its input from a human operator and translates this command into the motion of actuators, which move the mechanical structure. The high performance and highly powerful, Pneumatic machine vice together with the capacity for high volumes are suited for Holding Heavy Objects.

One form of inefficiency in current systems is due to the link between the flows of the two ports of the cylinder. This is because most valves use a single spool to control the flow in both ports. Because of this link, it is impossible to set the pressure levels in the two sides of the cylinder independently.

Therefore, the outlet side will develop a back-pressure, which acts in opposition to the direction of travel, which increases the pressure required on the inlet side to maintain motion. Since the force generated by the actuator is proportional to the pressure difference between the two sides, the actual pressures in the cylinder don’t affect the action of the cylinder.

Component required:

- Pneumatic Cylinder

- Air Control/ Flow Control valve

- Back Plate or supporting plate

Generally, Pneumatic cylinder operations are based on Pneumatic pump operation. Air is pumping to the Pneumatic cylinder by using Pneumatic pump system. It’s the manual operation.

Application:

Can be used where Mass Production is more.