Fabrication of Welding Slag Cleaning Machine

Synopsis

Welding is the process of joining of two materials by using filler rod, while joining the materials the high amount of heat is generated in welding surface, so oxidation can take place over the job, in order to prevent the oxidation the flux material is coated over the welded area.

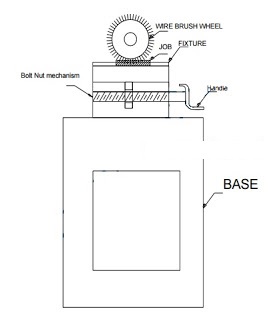

This flux coating is removed while send to the job for next operation like machining, painting etc, but it a terries process to clean the flux manually, and it need huge amount of skilled labor, in order to avoid that welding slag cleaning machine is used. This machine has a circular wire brush which is mounted over the shaft; also this shaft is connected with electric motor.

The job is hold in the fixture, this fixture setup is moved by rack and pinion arrangement ,so by this too and fro motion job will move front and back against the job ,so job will automatically cleaned easily.

Important Terminology In Welding Process:

Welding: A joining process that uses high temperature, pressure, and/or chemicals to fuse two materials together permanently for long time.

Welder: Either the person who performs a weld task or the power source that provides the electricity needed to perform an arc weld. Printed materials may use both meanings of the term.

Electric Arc: The area in which electricity jumps from the electrode to the work-piece.

Electrode: A device that conducts electricity. In welding, the electrode also can act as the filler metal

Flux: A non-metallic material used to protect the weld puddle (small pool of liquid metal) and solid metal from atmospheric contamination Flux-Cored

Arc Welding: An arc welding process that uses a continuously fed consumable electrode that contains flux in a hollowed-out center. It is also referred to as FCAW.

Slag: Cooled flux that forms on top of the bead.

ADVANTAGES:

1. Production cost is very low than other cleaning machine.

2. No need of purchase special machine.

3. It is mainly very useful to hold the lengthy plate(1.5 feet) in particular position.

5. Its operated and maintenance is simple than other cleaning machine.

6. It is compact and portable than other cleaning machine.

7. It is simple and rigid in construction than other cleaning machine.

8. Manufacturing cost in lesser than other cleaning machine.

DISADVANTAGE:

1. Small vibration occurs due to wire brush wheel attachment.

2. In order to avoid vibration the machine should be properly foundation with the floor.

Application:

This device find place in.

1.It is used almost in all types if industries (Large , Small & medium scale industries ).

2.This machine is mainly used in manufacturing -oriented industries.

3.This device is suitable to hold flat type plate. (maximum length 1.5 feet)

Post Comment

You must be logged in to post a comment.