FORGING METHODS

The forging methods are commonly used for changing the shape of the raw material in to the finished form in the forging shop are generally classified into two categories namely hand forging and power forging. These are being discussed as under

1. Hand forging

Hand forging is performed in the black smithy shop. The job is heated at the forging temperature in hearth and it is then brought on anvil using tong. It is then forged using hand hammers and other hand forging tools for imparting specific shape.

1.1 Forging Operations

The hand forging operations are

1. Upsetting

2. Bending

3. Drawing down

4. Cutting

5. Setting down

6. Punching

7. Flattening

8. Fullering

9. Forge Welding

10. Swaging

Some important hand forging operations are described as under.

(i) Drawing out

Drawing out is used to reduce the thickness of a bar and to increase its length. It may be carried out by working the metal over the horn the anvil as shown in Fig., then by hammering it on the anvil face.

The rounded horn of the anvil acts as a blunt edge, which forces the metal to flow lengthwise when struck by the hammer. For drawing down very heavy work, fuller may be used for drawing down a bar over the horn (round portion) of anvil.

(ii) Fullering

Fullering operation generally used in forging shop is shown in Fig. It involves heating the stock in the black smith hearth. Then heated stock is placed on the fuller fixed on anvil. A fuller is put over the sock and hammering is done to reduce the cross section of job at required point.

(iii) Upsetting

Upsetting is also known as jumping operation which is carried out to increase the thickness (or diameter) of a bar and to reduce its length. Generally, the increase in thickness

is only local, for example, when forming a bolt head. This operation is an operation just opposite to drawing and involves increasing the cross-sectional area usually by hammering or pressing in a direction parallel to the ingot axis. The length of the ingot decreases and following the path of least resistance it spreads out. The required shape is given the ingot by spreading it between two dies. Only that portion of the bar which is to be upset is heated locally. Or, the whole bar is heated and except for the portion to be upset, the rest is quenched in water so that upset will form only on the hot portion of the bar. In one method of upsetting, the bar is held in the tong and supported vertically on the anvil. The top edge of the bar is then hammered to form the upset on the bottom hot end of the bar. For upsetting, the blow of the hammer must be in line with the bar to prevent bending of the bar.

(iv) Bending

Bending is a very commonly used forging operation in forging shop to give a turn to a metal rod or plate. It is accompanied by spreading of the metal in the inside of the bend and narrowing at outside. The simplest method of bending a piece of metal in hand forging is to support it on the anvil and to strike its free end with a hammer When bent, the metal of the workpiece thins out round bend causing weakness. This can be overcome by upsetting the bar prior to bending.

(v) Cutting

Cutting is a main forging operation to cut out a metal rod or plate into two pieces with the help of a chisel and hammer when the metal is in red hot condition. A hot or cold cut (chisel) is used for cutting heated metal bars in a smithy shop. The hot set does not require hardening and tempering. Its cutting edge is keener than that of a cold set. Hot sets are manufactured from a tough variety of steel in order that they may cut through relatively soft red-hot metal with ease. While cutting, it is best to cut half through the workpiece to turn it over and cut through from the other end.

(vi) Punching

Punching is a main forging operation used for producing hole in metal plate by using a tool known as punch. The metal plate is placed over the hollow cylindrical die and punch is placed above it at required location where hole is being made. For punching a hole, the metal job must be at near welding heat and the punch is driven part way through the job with hammer blows. The work is then turned over and the hole is completed from the other side. The above said practice is adopted for thicker jobs.

(vii) Forge Welding

It is a process of joining two metal pieces to increase the length by pressing or hammering them when they are at forging temperature. It is performed in forging shop and hence sometimes it is called as forge welding.

2. Power Forging

Hand hammer blows impact will not be always sufficient enough to affect the proper plastic flow in a medium sized or heavy forging. It also causes fatigue to the hammer man. To have heavy impact or blow for more plastic deformation, power hammer are generally employed.

These hammers are operated by compressed air, steam, oil pressure, spring and gravity. They are generally classified as spring hammer and drop hammers. The capacity of these hammers is given by the total weight. A 100 kg hammer will be one of which the falling pans weigh 100 kg. The heavier these parts and greater the height from which they fall, the higher will be intensity of blow the hammer will provide. Power hammers are of different types e.g. spring power hammers, pneumatic power hammers etc. These hammers are named due to their construction, according to their way of operation and according to the type of fuel they use for getting the required power for operation. Besides these, a large number of forging presses are also used in forging work. Typical hammers are discussed in following in following paragraphs.

2.1 Spring Hammer

Spring hammer is commonly used for small forgings. It is light type of power hammer. The typical design of a spring hammer is shown in Fig. It consists of a heavy rigid frame carrying a vertical projection at its top. This projection acts as a housing of bearing in which the laminated spring oscillates. The rear end of this spring carries a connecting rod and the other front end a vertical top which carries weight and moves vertically up and down between fixed guides provided for this purpose. The connecting rod at its lower end is attached to an eccentric sheave, which is further connected to the crank wheel. Fox operating the hammer the treadle is pressed downwards which makes the sheave to rotate through the crank wheel and thus the laminated spring starts oscillating in the bearing. This oscillation of the spring is responsible for the up and down movement of the tup thus, the required blows are provided on the job to be forged. A hand lever is also equipped with this mechanical kind of hammer to adjust the stroke of the connecting rod and, hence the intensity of blows.

Eccentric type of spring hammer is the one in which a rotating eccentric disc is used for producing vibrations in the spring. It can be operated by means of a foot ring, known as treadle provided at the bottom and is connected to the shaft at the top through a vertical bar having a clutch at its end. The shaft at the top of hammer carries a pulley and a solid disc at the end. The pulley is driven by means of a belt from the line shaft or an electric motor.

The solid disc, at the, end of the shaft, carries a crank connected eccentrically to it which has a laminated spring at its lower end. The nip carrying the weight is suspended on a toggle joint connecting the two ends of the laminated spring. When the foot treadle is pressed the clutch engages with the shaft and the disc carrying the crank starts rotating which in turn produces fluctuations in the toggle joint of the machine. It makes the tup to move and down in vertical direction. The speed of blows entirely depends upon the speed of the driving pulley.Spring hammers may be made available in various capacities having the tup weights from 30 to 250 kg. Those having top weights 50 to 100 kg and speed of blows up to 300 per minute are in generally used in forging shop. These hammers have a common drawback in their springs getting broken very frequently due to severe vibrations during forging of the jobs in the forging shop.

2.2 Drop Hammers

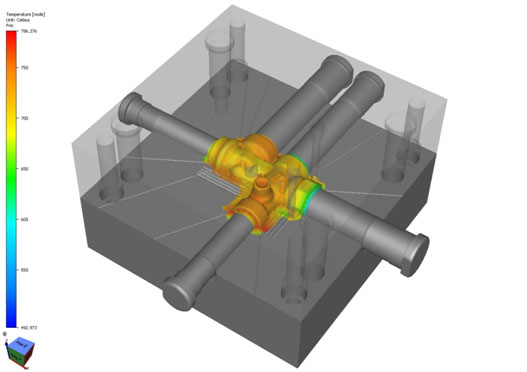

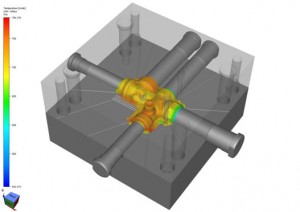

Drop hammers are operated hydraulically and are widely used for shaping parts by drop hammering a heated bar or billet into a die cavity as shown in Fig. A drop forging raises a massive weight and allows it to fall under gravity on close dies in which forge component is allowed to be compressed. The die incorporates its shape on to the hot work piece as shown in Fig. Drop hammers are commonly used for forging copper alloys and steel. Copied from Introduction to Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.