FORGING TEMPERATURES

A metal must be heated to a temperature at which it will possess high plastic properties to carry out the forging process. The metal work piece is heated to a proper temperature so that it gains required plastic properties before deformation, which are essential for satisfactory forging. Excessive temperatures may result in the burning of the metal. Insufficient temperatures will not introduce sufficient plasticity in the metal to shape it properly by hammering etc. Moreover, under these conditions, the cold working defects such as hardening and cracking may occur in the product.

The temperature to start the forging for soft, low carbon steels is 1,250 to 1,300°C, the temperature to finish forging is 800 to 840°C. The corresponding temperatures for high carbon and alloy steels which are hard in nature are 1100 to l140°C and 830 to 870°C. Wrought iron is best forged at a temperature little below 1,290°C. Non ferrous alloys like bronze and brass are heated to about 600 to 930°C, the aluminium and magnesium alloys to about 340 to 500°C.

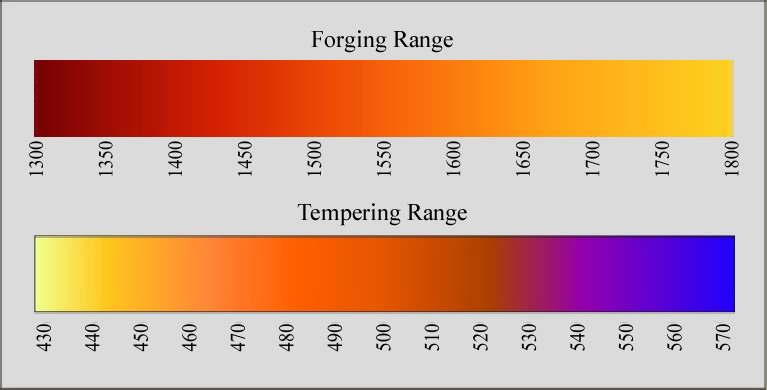

Forging temperature should be proper to get good results. Excessive temperature may result in the burning of the metal, which destroys the cohesion of the metal. Insufficient temperature will not introduce sufficient plasticity in the metal. The forging operation in metal is if finished at a lower temperature, it may lead to cold hardening and cracks may develop in it. However, excessive heating of the forgeable part may result in oxidization and hence material is wasted. The temperature of heating steel for hand forging can be estimated by the color of heat and which color of the light emitted by the heated steel. For accurate determinations of forging temperatures of the heated part, the optical pyrometers are generally used. Copied from Introduction to Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.