Functions of Electrode Coating Ingredients

The covering coating on the core wire consists of many materials which perform a number of functions as listed below:

1. Welding electrodes are used to join various similar and dissimilar metals as plain carbon steels, cast iron, copper, aluminium, magnesium and their alloys, stainless steels and other alloy steels.

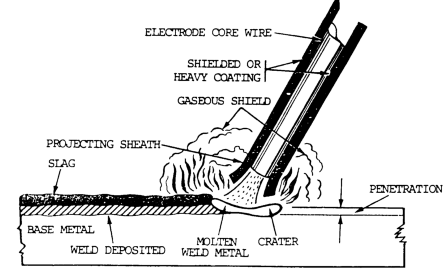

2. Slag forming ingredients, like silicates of magnesium, aluminium, sodium, potassium, iron oxide, china clay, mica etc., produce a slag which because of its light weight forms a layer on the molten metal and protects the same from atmospheric contamination.

3. Arc stabilizing constituents like calcium carbonate, potassium silicate, titanates, magnesium silicates, etc.; add to arc stability and ease of striking the same.

4. Gas shielding ingredients, like cellulose, wood, wood flour, starch, calcium carbonate etc. form a protective gas shield around the electrode end, arc and weld pool.

5. Deoxidizing elements like ferro-manganese, and ferro-silicon, refine the molten metal.

6. It limits spatter, produces a quiet arc and easily removable slag.

7. Alloying elements like ferro alloys of manganese, molybdenum etc., may be added to impart suitable properties and strength to the weld metal and to make good the loss of some of the elements, which vaporize while welding.

8. Iron powder in the coating improves arc behavior, bead appearance helps increase metal deposition rate and arc travel speed.

9. The covering improves penetration and surface finish.

10. Core wire melts faster than the covering, thus forming a sleeve of the coating which constricts and produces an arc with high concentrated heat.

11. Coating saves the welder from the radiations otherwise emitted from a bare electrode while the current flows through it during welding.

12. Proper coating ingredients produce weld metals resistant to hot and cold cracking. Suitable coating will improve metal deposition rates.

Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Songh.

Post Comment

You must be logged in to post a comment.