GAS WELDING PROCESSES

A fusion welding process which joins metals, using the heat of combustion of an oxygen /air and fuel gas (i.e. acetylene, hydrogen propane or butane) mixture is usually referred as ‘gas welding’. The intense heat (flame) thus produced melts and fuses together the edges of the parts to be welded, generally with the addition of a filler metal. Operation of gas welding is shown in Fig. The fuel gas generally employed is acetylene; however gases other than

acetylene can also be used though with lower flame temperature. Oxy-acetylene flame is the most versatile and hottest of all the flames produced by the combination of oxygen and other fuel gases. Other gases such as Hydrogen, Propane, Butane, Natural gas etc., may be used for some welding and brazing applications.

1. Oxy-Acetylent Welding

In this process, acetylene is mixed with oxygen in correct proportions in the welding torch and ignited. The flame resulting at the tip of the torch is sufficiently hot to melt and join the parent metal. The oxy-acetylene flame reaches a temperature of about 3300°C and thus can melt most of the ferrous and non-ferrous metals in common use. A filler metal rod or welding rod is generally added to the molten metal pool to build up the seam slightly for greater strength.

1.1 Types of Welding Flames

In oxy-acetylene welding, flame is the most important means to control the welding joint and the welding process. The correct type of flame is essential for the production of satisfactory welds. The flame must be of the proper size, shape and condition in order to operate with maximum efficiency. There are three basic types of oxy-acetylene flames.

1. Neutral welding flame (Acetylene and oxygen in equal proportions).

2. Carburizing welding flame or reducing (excess of acetylene).

3. Oxidizing welding flame (excess of oxygen).

Neutral Welding Flame

A neutral flame results when approximately equal volumes of oxygen and acetylene are mixed in the welding torch and burnt at the torch tip. The temperature of the neutral flame is of the order of about 5900°F (3260°C). It has a clear, well defined inner cone, indicating that the combustion is complete. The inner cone is light blue in color. It is surrounded by an outer flame envelope, produced by the combination of oxygen in the air and superheated carbon monoxide and hydrogen gases from the inner cone. This envelope is Usually a much darker blue than the inner cone. A neutral flame is named so because it affects no chemical change on the molten metal and, therefore will not oxidize or carburize the metal. The neutral flame is commonly used for the welding of mild steel, stainless steel, cast Iron, copper, and aluminium.

Carburising or Reducing Welding Flame

The carburizing or reducing flame has excess of acetylene and can be recognized by acetylene feather, which exists between the inner cone and the outer envelope. The outer flame envelope is longer than that of the neutral flame and is usually much brighter in color. With iron and steel, carburizing flame produces very hard, brittle substance known as iron carbide. A reducing flame may be distinguished from carburizing flame by the fact that a carburizing flame contains more acetylene than a reducing flame. A reducing flame has an approximate temperature of 3038°C. A carburizing-flame is used in the welding of lead and for carburizing (surface hardening) purpose. A reducing flame, on the other hand, does not carburize the metal; rather it ensures the absence of the oxidizing condition. It is used for welding with low alloy steel rods and for welding those metals, (e.g., non-ferrous) that do not tend to absorb carbon. This flame is very well used for welding high carbon steel.

Oxidising Welding flame

The oxidizing flame has an excess of oxygen over the acetylene. An oxidizing flame can be recognized by the small cone, which is shorter, much bluer in color and more pointed than that of the neutral flame. The outer flame envelope is much shorter and tends to fan out at the end. Such a flame makes a loud roaring sound. It is the hottest flame (temperature as high as 6300°F) produced by any oxy-fuel gas source. But the excess oxygen especially at high temperatures tends to combine with many metals to form hard, brittle, low strength oxides. Moreover, an excess of oxygen causes the weld bead and the surrounding area to have a scummy or dirty appearance. For these reasons, an oxidizing flame is of limited use in welding. It is not used in the welding of steel. A slightly oxidizing flame is helpful when welding (i) Copper-base metals (ii) Zinc-base metals and (iii) A few types of ferrous metals such as manganese steel and cast iron. The oxidizing atmosphere in these cases, create a basemetal oxide that protects the base metal.

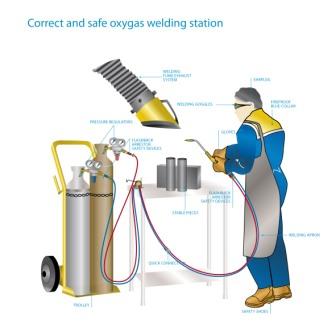

1.2 Gas Welding Equipments

An arrangement of oxy acetylene welding set up is shown in Fig. The basic tools and equipments used for oxy-acetylene welding are following:

Acetylene and oxygen gas is stored in compressed gas cylinders. These gas cylinders differ widely in capacity, design and colour code. However, in most of the countries, the standard size of these cylinders is 6 to 7 m3 and is painted black for oxygen and maroon for acetylene. An acetylene cylinder is filled with some absorptive material, which is saturated with a chemical solvent acetone. Acetone has the ability to absorb a large volume of acetylene and release it as the pressure falls. If large quantities of acetylene gas are being consumed, it is much cheaper to generate the gas at the place of use with the help of acetylene gas generators. Acetylene gas is generated by carbide-to-water method. Oxygen gas cylinders are usually equipped with about 40 litres of oxygen at a pressure of about 154 Kgf/cm2 at 21°C. To provide against dangerously excessive pressure, such as could occur if the cylinders were exposed to fire, every valve has a safety device to release the oxygen before there is any danger of rupturing the cylinders. Fragile discs and fusible plugs are usually provided in the cylinders valves in case it is subjected to danger.

Gas pressure regulators

Gas pressure regulators are employed for regulating the supply of acetylene and oxygen gas from cylinders. A pressure regulator is connected between the cylinder and hose leading to welding torch. The cylinder and hose connections have left-handed threads on the acetylene regulator while these are right handed on the oxygen regulator. A pressure regulator is fitted with two pressure gauges, one for indication of the gas pressure in the cylinder and the other for indication of the reduced pressure at which the gas is going out.

Welding torch

Fig shows the construction of the welding torch. It is a tool for mixing oxygen and acetylene in correct proportion and burning the mixture at the end of a tip. Gas flow to the torch is controlled with the help of two needle valves in the handle of the torch. There are two basic types of gas welding torches:

(1) Positive pressure (also known as medium or equal pressure), and

(2) Low pressure or injector type

The positive pressure type welding torch is the more common of the two types of oxyacetylene torches.

Torch tips

It is the portion of the welding apparatus through which the gases pass just prior to their ignition and burning. A great variety of interchangeable welding tips differing in size, shape and construction are available commercially. The tip sizes are identified by the diameter of the opening. The diameter of the tip opening used for welding depends upon the type of metal to be welded.

Hose pipes

The hose pipes are used for the supply of gases from the pressure regulators. The most common method of hose pipe fitting both oxygen and acetylene gas is the reinforced rubber hose pipe. Green is the standard color for oxygen hose, red for acetylene, and black hose for other industrially available welding gases.

Goggles

These are fitted with colored lenses and are used to protect the eyes from harmful heat and ultraviolet and infrared rays.

Gloves

These are required to protect the hands from any injury due to the heat of welding process.

Spark-lighter

It is used for frequent igniting the welding torch.

Filler rods

Gas welding can be done with or without using filler rod. When welding with the filler rod, it should be held at approximately 900 to the welding tip. Filler rods have the same or nearly the same chemical composition as the base metal. Metallurgical properties of the weld deposit can be controlled by the optimum choice of filler rod. Most of the filler rods for gas welding also contain deoxidizers to control the oxygen content of weld pool.

Fluxes

Fluxes are used in gas welding to remove the oxide film and to maintain a clean surface. These are usually employed for gas welding of aluminium, stainless steel, cast iron, brass and silicon bronze. They are available in the market in the form of dry powder, paste, or thick solutions. Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Songh.

Post Comment

You must be logged in to post a comment.