HOT EXTRUSION

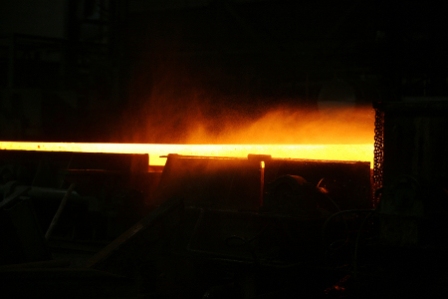

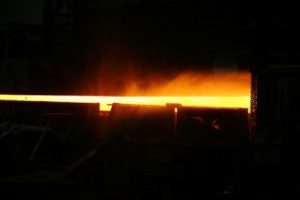

It is the process of enclosing the heated billet or slug of metal in a closed cavity and then pushing it to flow from only one die opening so that the metal will take the shape of the opening. The pressure is applied either hydraulically or mechanically. Extrusion process is identical to the squeezing of tooth paste out of the tooth paste tube. Tubes, rods, hose, casing, brass cartridge, moulding-trims, structural shapes, aircraft parts, gear profiles, cable sheathing etc. are some typical products of extrusion. Using extrusion process, it is possible to make components, which have a constant cross-section over any length as can be had by the rolling process. The intricacy in parts that can be obtained by extrusion is more than that of rolling, because the die required being very simple and easier to make. Also extrusion is a single pass process unlike rolling. The amount of reduction that is possible in extrusion is large. Generally brittle materials can also be easily extruded. It is possible to produce sharp corners and reentrant angles. It is also possible to get shapes with internal cavities in extrusion by the use of spider dies, which are explained later.

The extrusion setup consists of a cylinder container into which the heated billet or slug of metal is loaded. On one end of the container, the die plate with the necessary opening is fixed. From the other end, a plunger or ram compresses the metal billet against the container walls and the die plate, thus forcing it to flow through the die opening, acquiring the shape of the opening. The extruded metal is then carried by the metal handling system as it comes out of the die.

The extrusion ratio is defined as the ratio of cross- sectional area of the billet to that of the extruded section. The typical values of the extrusion ratio are 20 to 50. Horizontal hydraulic presses of capacities between 250 to 5500 tonnes are generally used for conventional extrusion. The pressure requirement for extrusion is varying from material to material. The extrusion pressure for a given material depends on the extrusion temperature, the reduction in area and the extrusion speed. Source Introduction of a Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.