Injection die Molding

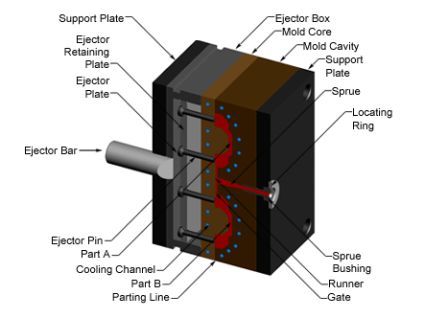

In this process, thermoplastic materials soften when heated and re-harden when cooled. No chemical change takes place during heating and cooling. Fig. illustrates the injection molding process. The process involves granular molding material is loaded into a hopper from where it is metered out in a heating cylinder by a feeding device. The exact amount of material is delivered to the cylinder which is required to fill the mold completely. The injection ram pushes the material into a heating cylinder and doing so pushing bushes a small amount of heated material out of other end of cylinder through the nozzle and screw bushing and into cavities of the closed mold. The metal cooled in rigid state in the mold. Then mold is opened and piece is ejected out material heating temperature is usually between 180°- 280°C. Mold is cooled in order to cool the mold articles. Automatic devices are commercially available to maintain mold temperature at required level. Injection molding is generally limited to forming thermoplastic materials, but equipment is available for converting the machines for molding thermosetting plastics and compounds of rubber. Copied from A Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

PLASTICS MOLDING PROCESSES

There are various methods of producing components from the plastics materials which are supplied in the granular, powder and other forms. Various plastics molding processes are:

1. Compression Molding.

2. Transfer Molding

3. Injection Molding.

4. Blow Molding.

5. Extrusion Molding

6. Calendaring.

7. Thermoforming.

8. Casting

Post Comment

You must be logged in to post a comment.