INTERNAL EXPANDING BREAK.

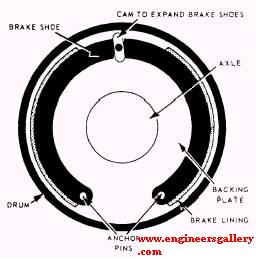

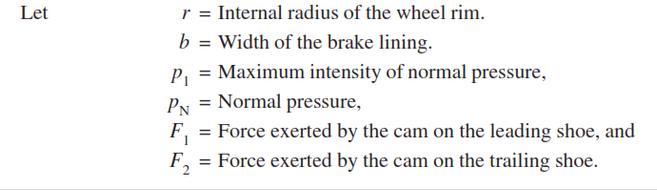

Internal expanding brakes are used almost exclusively as wheel brakes, but can be found on some cranes. This type of brake permits a more compact and economical construction. The brake shoes and brake-operating mechanism are supported on a backing plate or brake shield attached to the vehicle axle, as shown in figure 1. The brake drum, attached to the rotating wheel, acts as a cover for the shoe and operating mechanism and furnishes a frictional surface for the brake shoes.

The brake shoe of an internal expanding brake is forced outward against the drum to produce the braking action. One end of the shoe is hinged to the backing plate by an anchor pin, while the other end is unattached and can be moved in its support by the operating mechanism.When force from the operating mechanism is applied to the unattached end of the shoe, the shoe expands and brakes the wheel. A retracting spring returns the shoe to the original position when braking action is no longer required.

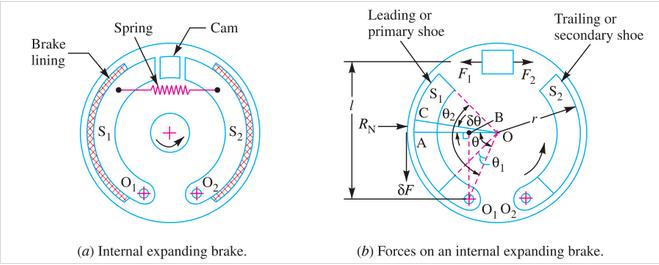

An internal expanding brake consists of two shoes S1 and S2. The outer surface of the shoes are lined with some friction material (usually with Ferodo) to increase the coefficient of friction and to prevent wearing away of the metal. Each shoe is pivoted at one end about a fixed fulcrum O1and O2 and made to contact a cam at the other end. When the cam rotates, the shoes are pushed outwards against the rim of the drum. The friction between the shoes and the drum produces the braking torque and hence reduces the speed of the drum. The shoes are normally held in

off position by a spring . The drum encloses the entire mechanism to keep out dust and moisture. This type of brake is commonly used in motor cars and light trucks.

We shall now consider the forces acting on such a brake, when the drum rotates in the anticlockwise direction. It may be noted that for the anticlockwise direction, the left hand shoe is known as leading or primary shoe while the right hand shoe is known as trailing or secondary shoe.

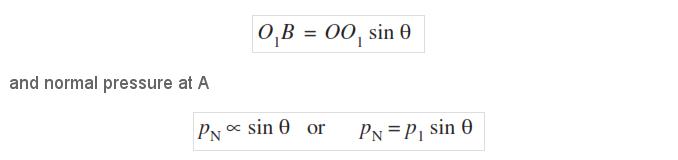

Consider a small element of the brake lining AC subtending an angle δθ at the centre. Let OA makes an angle θ with OO1. It is assumed that the pressure distribution on the shoe is nearly uniform, however the friction lining wears out more at the free end. Since the shoe turns about O1, therefore the rate of wear of the shoe lining at A will be proportional to the radial displacement of that point. The rate of wear of the shoe lining varies directly as the perpendicular distance from O1 to OA, i.e. O1B. From the geometry of the figure,

Reference engine mechanics and mechanical engineering

Post Comment

You must be logged in to post a comment.