Mechanical Project On Sensor Operated Vice

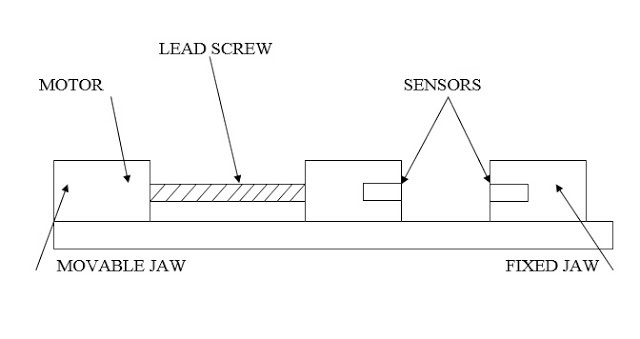

A vice is a mechanical screw apparatus used for holding or clamping a work piece to allow work to be performed on it with tools such as saws, planes, drills, mills, screwdrivers, sandpaper, etc. Vices usually have one fixed jaw and another, parallel, jaw which is moved towards or away from the fixed jaw by the screw.

An vice is used in metalworking applications. The jaws are made of soft or hard metal. The vice is bolted onto the top surface of the bench with the face of the fixed jaws just forward of the front edge of the bench. The bench height should be such that the top of the vice jaws is at or just below the elbow height of the user when standing upright. The vice may include other features such as a small anvil on the back of its body.

The nut in which the screw turns may be split so that, by means of a lever, it can be removed from the screw and the screw and movable jaw quickly slid into a suitable position at which point the nut is again closed onto the screw pneumatic screw, making setup not only faster, but more accurate as human error is reduced.

In over sensor operated vice a sensor is fitted in front off jaws Place work in vice. At jaws open position vice sense the work and the movable jaw moves automatically to fixed jaw and hold the work rigidly. After finishing the work we press a release button .the movable jaw move in back ward direction.

Sensor used For this Project:

In that the sensor is main roll the sensor is IR type –

There are two part of sensor one is transmitter anther one is receiver

- Transmitter transmit the ray

- Receiver receive the ray

If the ray is brake by work the motor start operated and move the movable jaw to front.

Advantages:

It is very easy in operation

It needs less man power

No need of more physical energy

Post Comment

You must be logged in to post a comment.