RACK AND PINION GEAR

Rack and pinion animations rack and pinion is a type of linear actuator that comprises a pair of gears which convert rotational motion into linear motion. The circular pinion engages teeth on a linear “gear” bar–the rack. Rotational motion applied to the pinion will cause the rack to move to the side, up to the limit of its travel. For example, in a rack railway, the rotation of a pinion mounted on a locomotive or a rail car engages a rack between the rails and pulls a train along a steep slope.

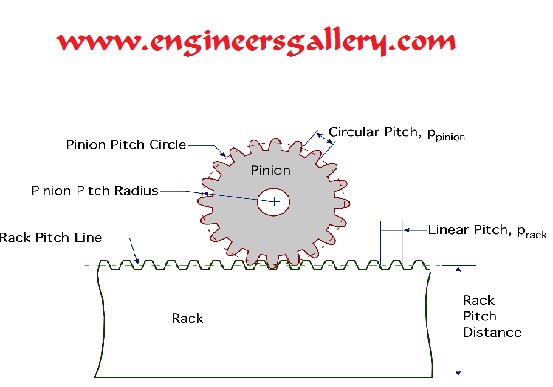

- A rack is a gear whose pitch diameter is infinite, resulting in a straight line pitch circle.

- Involute of a very large base circle approaches a straight line.

- Used to convert rotary motion to straight line motion.

- Used in machine tools.

A rack and pinion is a type of linear actuator that comprises a pair of gears which convert rotational motion into linear motion. A circular gear called “the pinion” engages teeth on a linear “gear” bar called “the rack”; rotational motion applied to the pinion causes the rack to move, thereby translating the rotational motion of the pinion into the linear motion of the rack.

For example, in a rack railway, the rotation of a pinion mounted on a locomotive or a rail car engages a rack between the rails and forces a train up a steep slope.

For every pair of conjugate involute profile, there is a basic rack. This basic rack is the profile of the conjugate gear of infinite pitch radius. (I.e. a toothed straight edge.)

A generating rack is a rack outline used to indicate tooth details and dimensions for the design of a generating tool, such as a hob or a gear shaper cutter.

The rack and pinion arrangement is commonly found in the steering mechanism of cars or other wheeled, steered vehicles. This arrangement provides a lesser mechanical advantage than other mechanisms such as recirculating ball, but much less backlash and greater feedback, or steering “feel”. The use of a variable rack (still using a normal pinion) was invented by Arthur E Bishop, so as to improve vehicle response and steering “feel” especially at high speeds, and that has been fitted to many new vehicles, after he created a specialized version of a net-shape warm press forging process to manufacture the racks to their final form, thus eliminating any subsequent need to machine the gear teeth.

Enclosed steering rack in an automobile for every pair of conjugate involute profile, there is a basic rack. This basic rack is the profile of the conjugate gear of infinite pitch radius.

A generating rack is a rack outline used to indicate tooth details and dimensions for the design of a generating tool, such as a hob or a gear shaper cutter.

Applications

Rack and pinion combinations are often used as part of a simple linear actuator, where the rotation of a shaft powered by hand or by a motor is converted to linear motion.

The rack carries the full load of the actuator directly and so the driving pinion is usually small, so that the gear ratio reduces the torque required. This force, thus torque, may still be substantial and so it is common for there to be a reduction gear immediately before this by either a gear or worm gear reduction. Rack gears have a higher ratio, thus require a greater driving torque, than screw actuators.

Reference : Wikipedia

Post Comment

You must be logged in to post a comment.