Metal Inert Gas Welding (MIG)

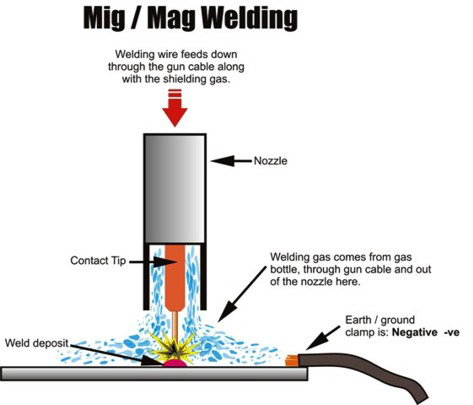

Metal inert gas arc welding (MIG) or more appropriately called as gas metal arc welding (GMAW) utilizes a consumable electrode and hence, the term metal appears in the title. There are other gas shielded arc welding processes utilizing the consumable electrodes, such as flux cored arc welding (FCAW) all of which can be termed under MIG. Though gas tungsten arc welding (GTAW) can be used to weld all types of metals, it is more suitable for thin sheets. When thicker sheets are to be welded, the filler metal requirement makes GTAW difficult to use. In this situation, the GMAW comes handy. The typical setup for GMAW or MIG welding process is shown in Fig. The consumable electrode is in the form of a wire reel which is fed at a constant rate, through the feed rollers. The welding torch is connected to the gas supply cylinder which provides the necessary inert gas. The electrode and the work-piece are connected to the welding power supply. The power supplies are always of the constant voltage type only. The current from the welding machine is changed by the rate of feeding of the electrode wire. Normally DC arc welding machines are used for GMAW with electrode positive (DCRP). The DCRP increases the metal deposition rate and also provides for a stable arc and smooth electrode metal transfer. With DCSP, the arc becomes highly unstable and also results in a large spatter. But special electrodes having calcium and titanium oxide mixtures as coatings are found to be good for welding steel with DCSP. In the GMAW process, the filler metal is transferred from the electrode to the joint. Depending on the current and voltage used for a given electrode, the metal transfer is done in different ways. Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.