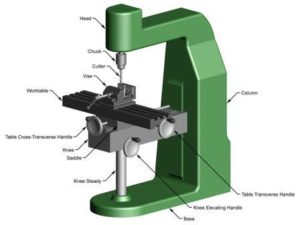

MILLING MACHINE

A milling machine is a machine tool that removes metal as the work is fed against a rotating multi point cutter. The milling cutter rotates at high speed and it removes metal at a very fast rate with the help of multiple cutting edges. One or more number of cutters can be mounted simultaneously on the arbor of milling machine. This is the reason that a milling machine finds wide application in production work. Milling machine is used for machining flat surfaces, contoured surfaces, surfaces of revolution, external and internal threads, and helical surfaces of various cross-sections. Typical components produced by a milling are given in Fig. In many applications, due to its higher production rate and accuracy, milling machine has even replaced shapers and slotters.

PRINCIPLE OF MILLING

In milling machine, the metal is cut by means of a rotating cutter having multiple cutting edges. For cutting operation, the work piece is fed against the rotary cutter. As the work piece moves against the cutting edges of milling cutter, metal is removed in form chips of trochoid shape. Machined surface is formed in one or more passes of the work. The work to be machined is held in a vice, a rotary table, a three jaw chuck, an index head, between centers, in a special fixture or bolted to machine table. The rotatory speed of the cutting tool and the feed rate of the work piece depend upon the type of material being machined. Source Introduction of Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.