MILLING METHODS

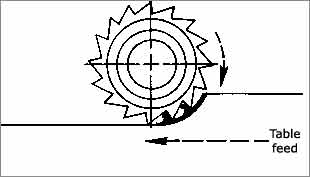

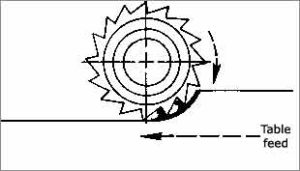

1. UP-Milling or Conventional Milling Procedure

In the up-milling or conventional milling, as shown in Fig., the metal is removed in form of small chips by a cutter rotating against the direction of travel of the work piece. In this type of milling, the chip thickness is minimum at the start of the cut and maximum at the end of cut. As a result the cutting force also varies from zero to the maximum value per tooth movement of the milling cutter. The major disadvantages of up-milling process are the tendency of cutting force to lift the work from the fixtures and poor surface finish obtained. But being a safer process, it is commonly used method of milling.

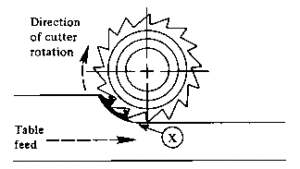

2. Down-Milling or Climb Milling

Down milling is shown in Fig. It is also known as climb milling. In this method, the metal is removed by a cutter rotating in the same direction of feed of the work piece. The effect of this is that the teeth cut downward instead of upwards. Chip thickness is maximum at the start of the cut and minimum in the end. In this method, it is claimed that there is less friction involved and consequently less heat is generated on the contact surface of the cutter and work piece. Climb milling can be used advantageously on many kinds of work to increase the number of pieces per sharpening and to produce a better finish. With climb milling, saws cut long thin slots more satisfactorily than with standard milling. Another advantage is that slightly lower power consumption is obtainable by climb milling, since there is no need to drive the table against the cutter. Source Introduction of Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.