Paper Cutting And Rewinding Machine Mechanical Project

ABSTRACT

Paper Cutting and Rewinding Machine is one of the simplest machine which cuts rolled paper in needed amount and re-winded form. The conventional paper rewinding machine has complex mechanism and bulk size. We made some modification to the conventional machine and eliminating its defects. The main peculiarity of machine is its simplicity, reduced size, weight. And also reduces floor space. This project can be directly implemented to paper cutting and rewinding machines in Paper mills. This machine can also use in textile mills, plastic and rubber sheets cutting and rewinding process in various industries by changing its cutting components.

By applying these modifications to the conventional machine reduce maintenance and servicing cost, floor area and overhead expenditures. It is well suited for small scale industries.

See also: Automatic paper cutting machine using Geneva mechanism

COMPONENTS OF PAPER CUTTING AND REWINDING MACHINE

1) BASIC FRAME

The entire unit is mounted on a rigid frame. The frame is made of mild steel C- Channels (75X40 mm) connected in rectangular form and weld at their joints.

2) ROLLERS

The paper rotating element in this device is the ϕ 89 mm outer diameter rollers with ϕ 40 mm outer diameter journals, which made up of three components.

1) G. I Hollow Pipe of ϕ 89 mm outer Diameter.

2) M.S Rod of ϕ 40 mm Diameter.

3) M.S Circular Plate of ϕ 81 mm Diameter.

The rotation of motor is transferred to the one of the four rollers on which cut paper is mounting in operation. The rotating roll makes all other three rollers to rotate. The roller is supported at its two ends by Plummer block with ball bearing blocks. The main functions of roller are to favor the cutting operation by moving paper and rewind it to rolls.

4) PLUMMER BLOCK

The roller is supported at the two ends with the help of Plummer block fitted with ϕ 40 mm diameter Ball bearings.

5) BEARINGS

Ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.

6) INDUCTION MOTOR

An induction or asynchronous motor is an AC motor in which all electromagnetic energy is transferred by inductive coupling from a primary winding to a secondary winding, the two windings being separated by an air gap.

7) SINGLE V-BELT AND PULLEY SYSTEM

Vee belts (also known as V-belt or wedge rope) solved the slippage and alignment problem. It is now the basic belt for power transmission. They provide the best combination of traction, speed of movement, load of the bearings, and long service life. They are generally endless, and their general cross-section shape is trapezoidal (hence the name “V”).

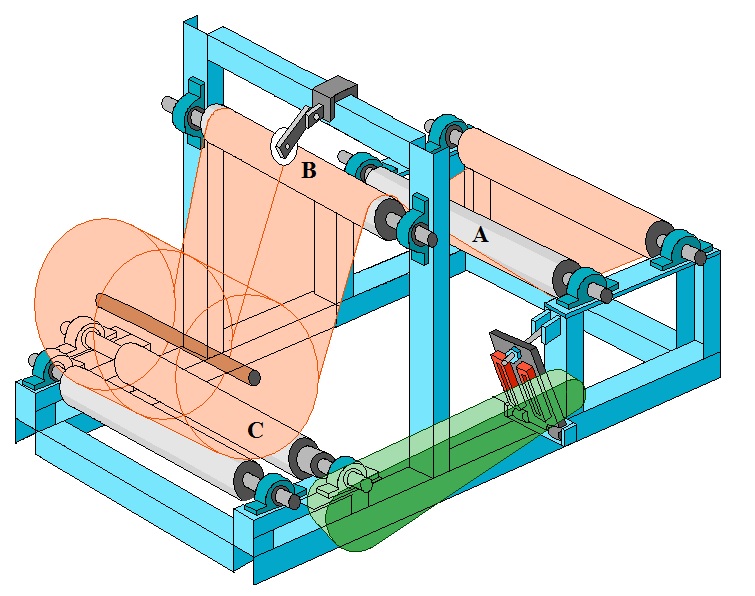

WORKING OF MACHINE

As we give number of modifications it is necessary to briefly explain working procedure of machine. When the paper being manufactured in paper mill it is not of standard size an also get torn out at the edges. And here is the need of re-winding machine. The roll of paper manufactured is mounted on the roll (A). In our machine we have given the self-aligning bearing with inner extended ring for ease in mounting and urn-mounting.

Then paper is passed around roll (B) to ensure that paper remain straight and tight. Then it passed through the cutter and grooved roll on top of machine, where it is cut. Because of our modification to this cutter roll the wt. ofmachine is decreased.

Then the paper which is cut is come to the roll at bottom, The roll is powered by 1 Hp motor with 1440 rpm. This rotating roll makes other roll (C) to rotate and not only wound the paper but also pull the paper to make the operation going.

Advantages

1) It is more compact as compared with conventional one.

2) Operation is simple Because of eliminating complex mechanisms.

3) Saving of floor space as motor is adjusted inside the structure.

4) New cutter clamping assembly given will eliminate the biggest disadvantage of machine i.e. high weight.

Post Comment

You must be logged in to post a comment.