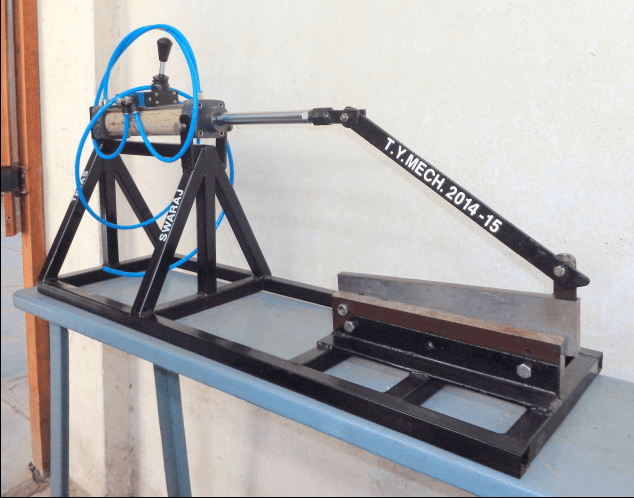

Pneumatic Sheet Metal Shearing/Cutting Machine

Synopsis:

The objective of the project is to prepare a machine which cuts sheet metal without human efforts but operates pneumatically. Compressed air is used as working media. The compressed air moves the blades of machine to cut the sheet of metal.

The idea of the project generated due to a manual sheet metal sheering machine in workshop of our college. In that machine sheet metal is placed in between the two sheering blades of machine and the lever is pulled down to move the upper movable blade and cut the work-piece.

See Similar Project:

But in that machine large force is required which can make tire to a worker who continuously works on it for mass production in large scale industry; so to reduce the human efforts pneumatic machine should chose. Hence for some development of machine, we have chosen this subject for our project. We hope that a good idea will develop and we can use it in many industries in surrounding and our practical knowledge, team-working skill, leadership skills will be improved.

Introduction :

In shearing or cutting operation as or blade descends upon the metal, the pressure exerted by the blade first cause the plastic deformation of the metal. Since the clearance between the two blades is very small, the plastic deformation takes place in a localized area and the metal adjacent to the cutting edges of the blade edges becomes highly stressed, which causes the fracture to start on both sides of the sheet as the deformation progresses and the sheet is sheared.

Types of shearing Machine:

1) Pneumatically operated

2) Hydraulically operated

3) Rack and pinion operated

4) Spring operated

Brief description of all the types is as follows.

1) Pneumatically operated:-

Here the advancement of the header is carried out in the upward and the downward direction using the pneumatic double acting piston and cylinder unit arrangement along with the foot operated direction control valve. In this type of machine high pressure air is used as the working fluid for the transfer of power and the motion.

Working:

Initially the air-compressor is started and allowed the receiver tank air pressure to reach up to 8 bar. The supply air is then passed to the manifold through FRL unit to condition the air and eligible to industrial use.

From the manifold a separate supply for the machine is taken out and given to ON-OFF switch, so as to operate the machine at will without interrupting the running of compressor.

Then the pipe carries compressed air first to machine’s Direction Control Valve. At position ‘A’ shows the non-actuated circuit diagram. At this position the piston is steady and locked. All ports are in closed condition.

At position ‘B’, the DC valve is at left hand position as shown in figure. The cap end port & pressure port get connected to each other and the rod end port gets connected to the exhaust port. The compressed air comes in the cap end of the cylinder and pushes the pistons outwards. The air already present in the rod end side is pushed out of the cylinder.

When the piston moves outwards, the force is transmitted through the connecting link and the upper blade moves downwards. Before the actuating DC valve the sheet is inserted in between the upper & lower blades. As upper blade moves downwards, the stress is generated in the sheet metal and goes beyond ultimate shear stress of sheet metal. And thus the shearing action takes place.

Now the DC valve is operated to come at position ‘C’, as shown in figure. The rod end port & pressure port get connected to each other and the cap end port gets connected to the exhaust port. The compressed air comes in the rod end of the cylinder and pushes the pistons inwards. The air already present in the cap end side is pushed out of the cylinder.

The sheet metal is either again inserted for further cutting in case of large pieces; the small cut pieces are removed and the next sheet is inserted to cut.

Merits-

1. Hydraulics present certain advantages over pneumatics, but in a given application, pneumatic powered equipment is more suitable, particularly in industries where the factory units are plumbed for compressed air.

2. Moreover, to avoid corrosive actions, oil or lubricants are added so that friction effects can be reduced.

3. Compressed air is used in most of the machines and in some cases compressed carbon dioxide, whereas cutting process is become easy.

4. Fast cutting action is carried out.

5. Cutting without bending is achieved.

Demerits–

1. Sheet more than 2 mm thickness cannot cut easily.

2. Compressed air is must.

3. Foundation is required also safety major must be taken.

Post Comment

You must be logged in to post a comment.