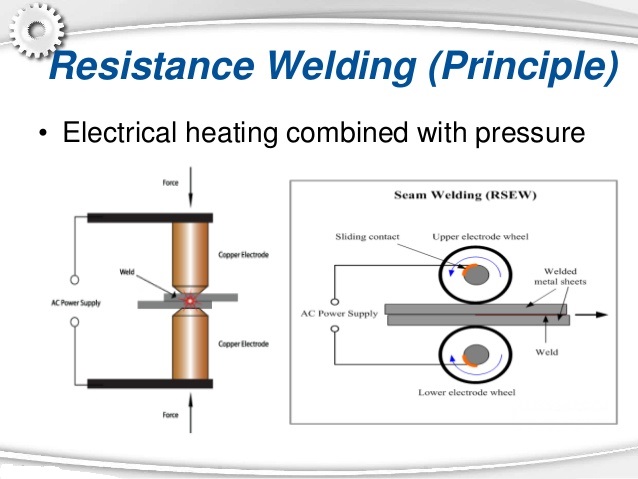

RESISTANCE WELDING

In resistance welding the metal parts to be joined are heated by their resistance to the flow of an electrical current. Usually this is the only source of heat, but a few of the welding operations combine resistance heating with arc heating, and possibly with combustion of metal in the arc. The process applies to practically all metals and most combinations of pure metals and those alloys, which have only a limited plastic range, are welded by heating the parts to fusion (melting). Some alloys, however, may welded without fusion; instead, the parts are heated to a plastic state at which the applied pressure causes their crystalline structures to grow together. The welding of dissimilar metals may be accomplished by melting both metals frequently only the metal with the lower melting point is melted, and an alloy bond is formed at the surface of the unmelted metal.

In resistance welding processes no fluxes are employed, the filler metal is rarely used and the joints are usually of the lap type. The amount of heat generated in the workpiece depend on the following factors:

(1) Magnitude of the current,

(2) Resistance of the current conducting path, and Mathematically, H = IVt = I(IR)t = I^2 * Rt

Where H = heat generated in joules

I = current in Amp.

R = resistance in ohms

t = time of current flow in seconds.

Types of Resistance welding

The major types of resistance welding are given as under:

(1) Spot Welding

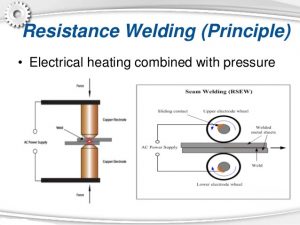

(2) Seam Welding

(3) Projection Welding

(4) Resistance Butt Welding

(5) Flash Butt Welding

(6) Percussion Welding

(7) High Frequency Resistance Welding

(8) High Frequency Induction Welding

Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.