Safety Recommendations for ARC Welding

The beginner in the field of arc welding must go through and become familiar with these general safety recommendations which are given as under.

1. The body or the frame of the welding machine shall be efficiently earthed. Pipe lines containing gases or inflammable liquids or conduits carrying electrical conductors shall not be used for a ground return circuit All earth connections shall be mechanically strong and electrically adequate for the required current.

2. Welding arc in addition to being very is a source of infra-red and ultra-violet light also; consequently the operator must use either helmet or a hand-shield fitted with a special filter glass to protect eyes.

3. Excess ultra-violet light can cause an effect similar to sunburn on the skin of the welder.

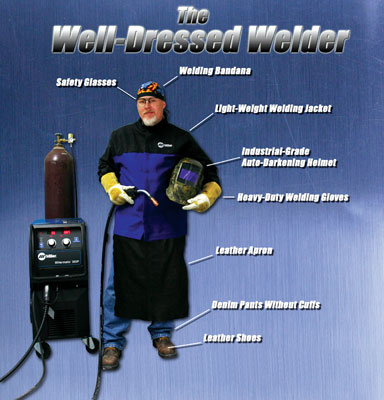

4. The welder’s body and clothing are protected from radiation and burns caused by sparks and flying globules of molten metal with the help of the following:

5. Gloves protect the hands of a welder.

6. Leather or asbestos apron is very useful to protect welder’s clothes and his trunk and thighs while seated he is doing welding.

7. For overhead welding, some form of protection for the head is required.

8. Leather skull cap or peaked cap will do the needful.

9. Leather jackets and 1ather leggings are also available as clothes for body protection.

10. Welding equipment shall be inspected periodically and maintained in safe working order at all times.

11. Arc welding machines should be of suitable quality.

12. All parts of welding set shall be suitably enclosed and protected to meet the usual service conditions.

13. Welders and workers need to be protected from welding rays, f1ying sparks, metal globules and metal spatter, hot slag particles, hot stubs, fumes and gases when welding in confined spaces, e.g., rail tank wagon, falling when welding at a height from the ground.

14. In AC arc welding machines, in transformers, the secondary circuit shall be thoroughly insulated from the primary. Input terminal shall be completely enclosed and accessible only by means of tools.

15. The primary side of the transformer shall be provided with suitable wire terminals inside the machine case.

16. Welding (secondary) terminals shall be so arranged that current carrying parts are not exposed to accidental contact.

17. In a transformer, the welding circuit should be quite separate from power circuit, so that there is no risk of the welder suffering serious shock or burns through power voltage appearing across the electric holder.

18. At or near each welding machine, a disconnecting switch shall provide.

19. Control apparatus provided with the welding machine shall enclose except for the operating wheels, levers, etc.

20. Transformer windings be suction or compressed-air cleaned periodically.

21. Before undertaking any maintenance work on welding machine disconnects them from the main supply.

22. As regards other arc welding equipments, electrode holders should be soundly connected to the welding lead.

23. They should be of adequate rating for the maximum welding current to prevent them from heating up and be coming too hot to handle.

24. Electrode holder sha1l be provided with discs or shields to protect the hands of the welder from heat of the arc. Installation of all metallic of current carrying parts, including the jaws which grip the electrodes, is recommended.

25. Hot electrode holders shall not be permitted to dip in water because the retained moisture may cause an electric shock.

26. Welding cables shall be of completely insulated, flexible type. They should be capable of handling the maximum current requirements of the work in progress, taking into account the duty cycle under which the welder is working in case the cable insulation is damaged, do not operate the equipment.

27. The welding cable should be free from repair or splices up to a minimum distance of three metres from the electrode holder.

28. Fully insulated cable connectors of capacity at least equivalent to that of the cable shall be used to connect two cables together.

29. Welding cables shall be kept dry and free from grease and oil to avoid premature breakdown of insulation.

30. Arc welding machines should be properly ground (earthed).

31. Construction of arc welding machines should be such that they can operate satisfactorily even under conditions of saltish or moist air as in coastal areas, dust, smoke, fumes and gases, excessive shock or vibrations, steam and corrosive atmosphere, etc.

32. One should not work on the wiring of an arc welding machine unless qualified to do so.

33. Welding equipment used in the open and shall be protected from weather conditions. If it has been wetted it shall be thoroughly dried before being used.

34. Proper terminals should be used on the arc welding machines for the power line voltage connection.

35. Neither terminal of the welding generator shall be bonded to the frame of the welding machine.

36. Periodically clear out the accumulated dust from the welding machine with suction cleaner as this will not blow dust into other parts of the machine.

37. Over greasing may foul the commutators of DC generator.

38. Check and, if necessary, clean commutators of DC generator periodically, using fine sand paper.

39. Excessive sparking may result in a worn commutator of DC generator which may be cured by skimming in a lathe.

40. Brushes should move freely and have adequate spring tension. This can be tested by lifting and releasing them. Brushes should snap be firmly against the commutator of DC generator.

41. Greasing points need attention periodically.

42. Switch contacts should be cleaned periodically.

Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.