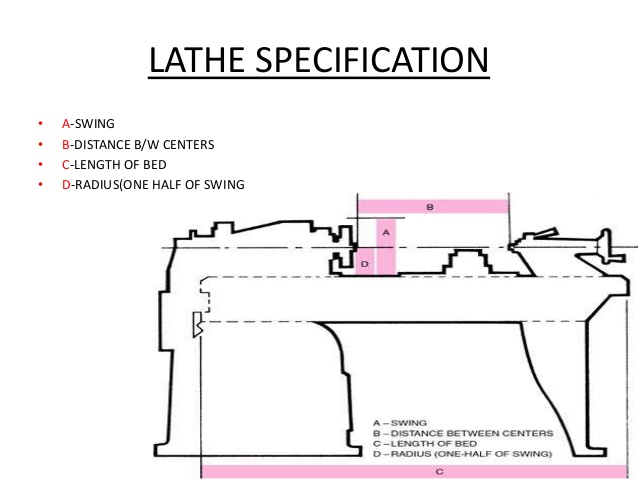

SPECIFICATION OF LATHE

The size of a lathe is generally specified by the following means:

(a) Swing or maximum diameter that can be rotated over the bed ways

(b) Maximum length of the job that can be held between head stock and tail stock centres

(c) Bed length, which may include head stock length also

(d) Maximum diameter of the bar that can pass through spindle or collect chuck of capstan lathe.

Fig. illustrates the elements involved in specifications of a lathe. The following data also contributes to specify a common lathe machine.

(i) Maximum swing over bed

(ii) Maximum swing over carriage

(iii) Height of centers over bed

(iv) Maximum distance between centers

(v) Length of bed

(vi) Width of bed

(vii) Morse taper of center

(viii) Diameter of hole through spindle

(ix) Face plate diameter

(x) Size of tool post

(xi) Number of spindle speeds

(xii) Lead screw diameter and number of threads per cm.

(xiii) Size of electrical motor

(xiv) Pitch range of metric and inch threads etc.

Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.